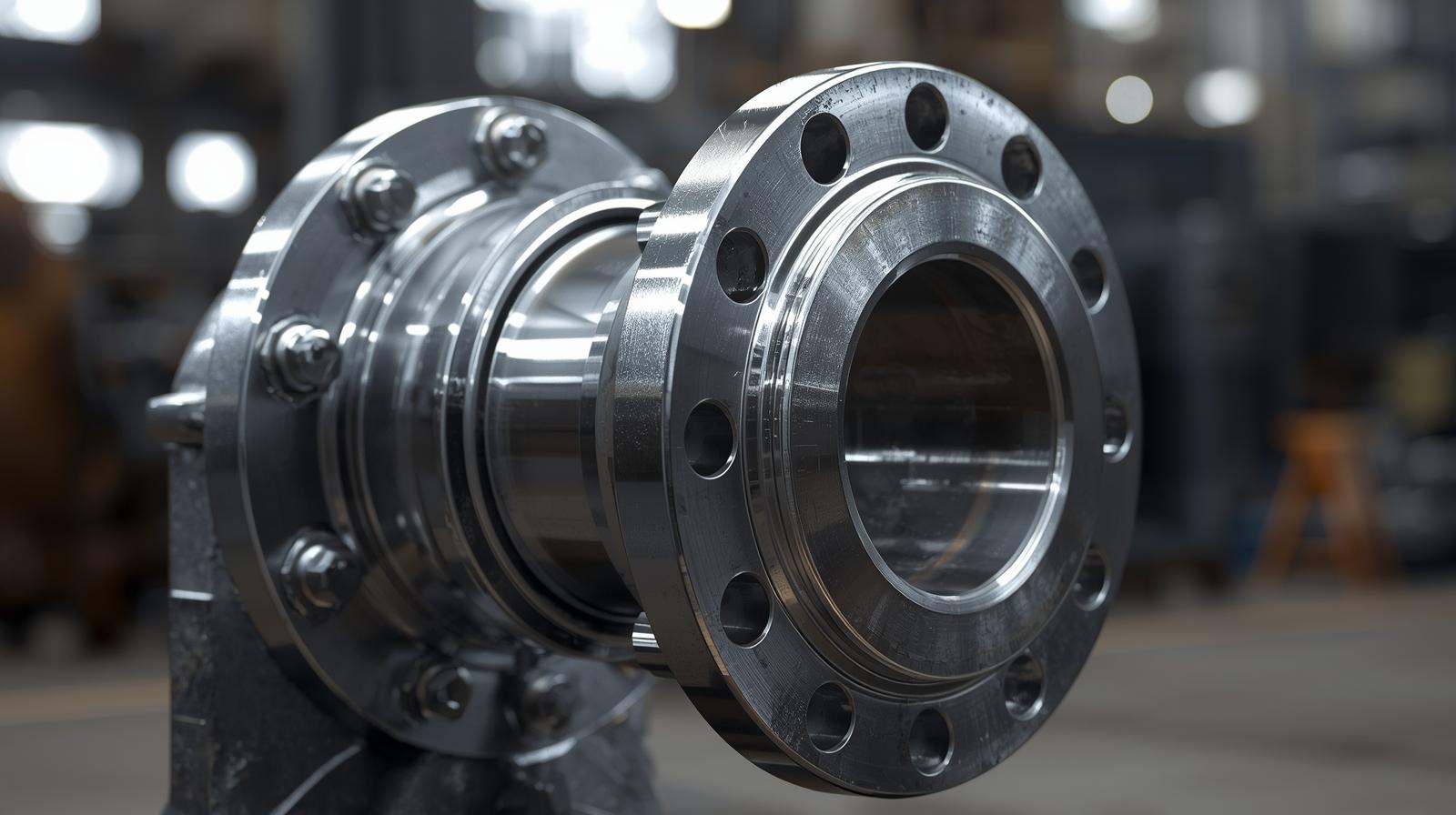

High Strength Flange Coupling Manufacturer: Reinforcing Torque Integrity Across Heavy Industries

In industries like mining, metallurgy, and heavy transport, torque failure is not an option. A single misalignment or material weakness in a flange coupling can cause costly downtime and machine damage.

Dingjian, as a professional high strength flange coupling manufacturer, focuses on torque reliability and material endurance — delivering couplings that handle continuous high loads, shocks, and rotational stress without losing precision.

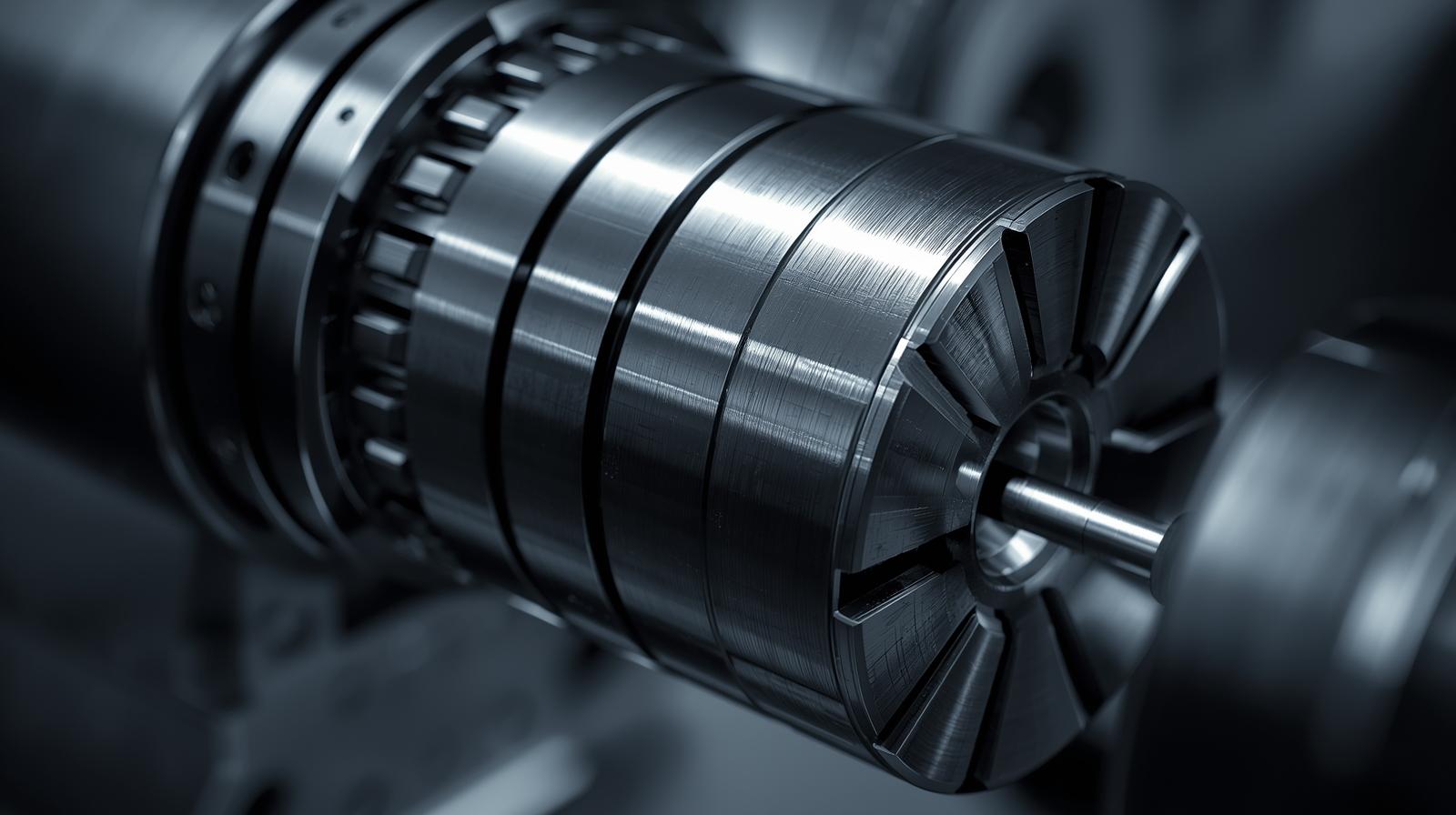

Material Strength and Structural Logic Behind Flange Couplings

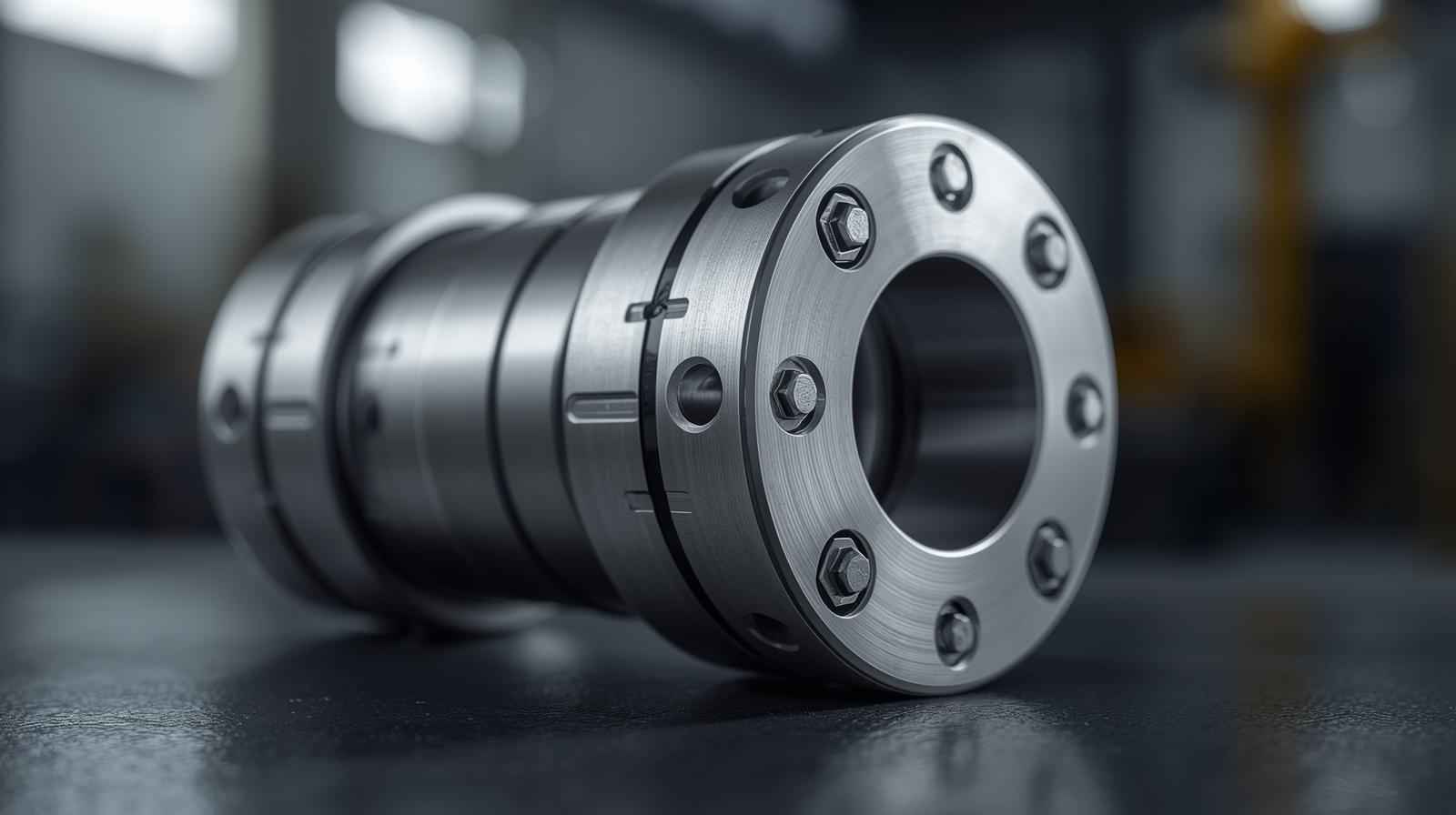

A flange coupling connects two rotating shafts via bolted flanges. Unlike flexible couplings, it offers rigid and secure torque transmission.

High-strength versions are engineered from heat-treated alloy steels and undergo CNC machining with fine-tolerance alignment.

Each flange and bolt circle is designed to:

-

Distribute torque evenly across the joint

-

Maintain axial alignment under load

-

Prevent fretting or bolt fatigue during vibration

-

Support rotational speeds exceeding 3000 RPM

This combination of material science and geometry precision allows Dingjian’s couplings to perform reliably in turbines, compressors, and forging equipment.

Traditional Flange Designs vs. Reinforced High-Strength Systems

| Parameter | Conventional Flange Coupling | Dingjian High-Strength Flange Coupling |

|---|---|---|

| Material Composition | Mild steel | Alloy steel / 42CrMo / stainless |

| Bolt Pattern | Standard circle | Load-optimized reinforced pattern |

| Torque Capacity | Limited | Up to 1.5× higher load-bearing |

| Machining Accuracy | ±0.05 mm | ±0.01 mm CNC finish |

| Surface Protection | Basic coating | Nitriding / phosphate / anti-corrosion |

| Maintenance Interval | Short | Extended with minimal bolt wear |

The upgraded flange structure improves torsional stiffness, reduces stress concentration, and enhances joint reliability — making it suitable for heavy machinery operating 24/7.

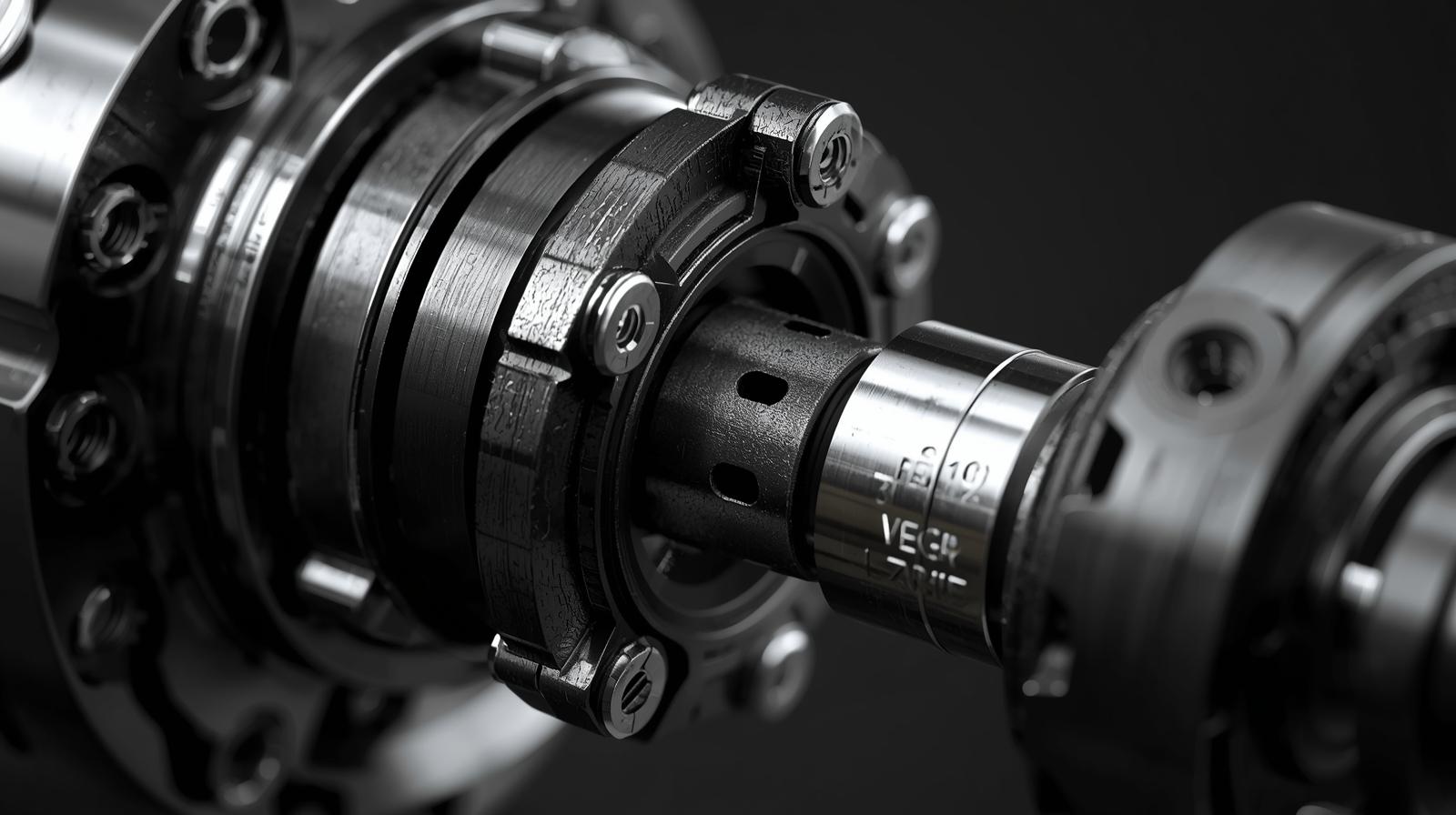

Engineering Solutions for Long-Term Torque Stability

Dingjian’s production process integrates advanced torque simulation and finite element analysis (FEA) to optimize coupling geometry and reduce bolt stress concentration.

Technical Enhancements Include:

-

Finite Element Simulation: Predicts stress zones under variable torque loads.

-

Bolt Preload Calculation: Ensures uniform clamping pressure to prevent slippage.

-

Dynamic Balancing: Achieves smooth rotation, eliminating vibration at high RPM.

-

Thermal Conditioning: Heat-treated structure maintains strength under 180°C.

-

Surface Hardening: Nitriding increases wear resistance for long-term service.

This engineering approach ensures consistent performance even in extreme working conditions, from rolling mills to marine propulsion systems.

Where Strength Meets Reliability

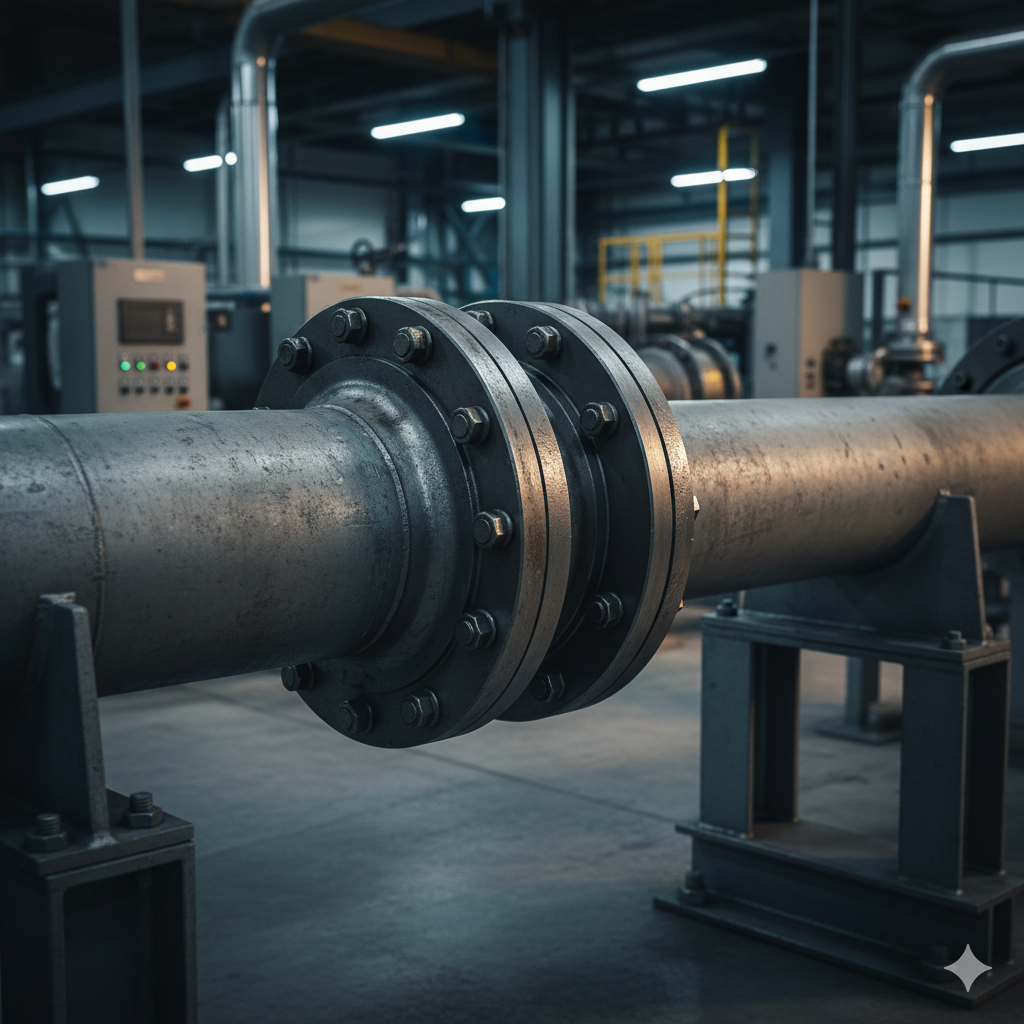

High-strength flange couplings are critical across heavy-duty applications that require consistent torque delivery and mechanical precision:

-

Mining conveyors & crushers – absorb shock from heavy material loads

-

Cement kilns & mixers – resist continuous torsional vibration

-

Hydraulic press systems – maintain torque lock under compression cycles

-

Marine propulsion shafts – handle constant torque in corrosive environments

-

Power generation turbines – ensure alignment stability under speed variation

Each application benefits from low runout, rigid structure, and balanced torque flow, ensuring both safety and efficiency.

Practical Selection Guide: Matching Strength to System Requirements

| Selection Criterion | Key Consideration | Recommended Option |

|---|---|---|

| Torque Rating | Maximum transmitted torque | Choose ≥1.2× nominal torque |

| Material | Corrosion / temperature exposure | Alloy steel or stainless |

| Bolt Design | Vibration resistance | High-tensile bolts with locking washers |

| Bore Fit | Shaft precision tolerance | H7/h6 interference fit |

| Environment | Dust / moisture / heat | Apply anti-rust & phosphate coating |

Tip: For heavy-duty transmission lines, opt for two-piece flange couplings with preloaded bolts to maintain consistent pressure and ease maintenance.

Common Technical Queries

Q1: How do high-strength flange couplings handle torque overloads?

By distributing torque through multiple bolts and flanges, minimizing stress concentration.

Q2: What’s the typical lifespan under full load?

With proper lubrication and maintenance, 3–5 years of continuous operation.

Q3: Are these couplings suitable for vertical drives?

Yes — flange-type couplings maintain perfect axial alignment even in vertical setups.

Q4: Can Dingjian provide torque testing certificates?

Each unit includes a torque verification report before shipment.

Building Reliable Motion Connections That Last

High-strength flange couplings are the foundation of mechanical reliability — small in size but critical in performance.

With advanced materials, controlled torque design, and decades of manufacturing experience, Dingjian ensures your power transmission system runs with stability, safety, and strength.

To request a technical consultation or a custom quote, please visit the official homepage or contact us directly via the contact page.