CNC Machine Rigid Coupling Supplier: Ensuring Precision Torque in High-Speed Machining

Every CNC spindle’s accuracy depends on what connects it to its drive source — the coupling.

Even a fraction of backlash or misalignment between the motor and feed screw can lead to micron-level machining errors.

As a professional supplier of rigid couplings for CNC machines, Dingjian designs and manufactures torque connectors that sustain stability, precision, and vibration control in high-speed machining centers.

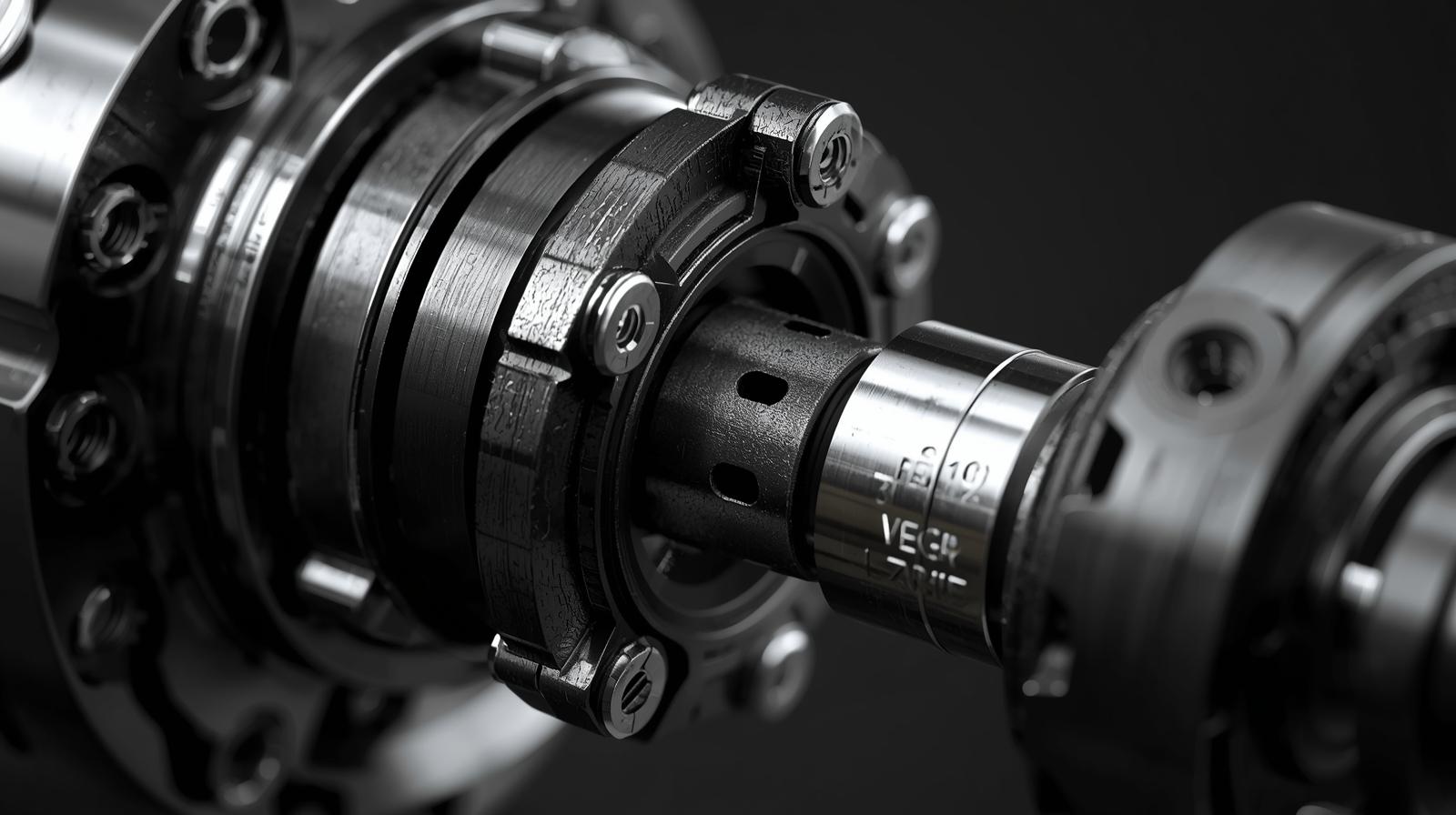

The Role of a Rigid Coupling in CNC Transmission Systems

In CNC systems, rigid couplings serve as the zero-flex interface between the servo motor and the ballscrew or spindle.

Their purpose is not to absorb motion but to preserve it — ensuring that every degree of motor rotation is accurately transferred to the cutting tool.

Key benefits of rigid coupling in CNC drives:

-

Zero torsional deflection: essential for high-resolution servo feedback.

-

Stable motion path: maintains positional accuracy during load reversal.

-

No backlash or slip: ideal for simultaneous multi-axis operation.

-

Compact design: supports confined CNC motor housings.

Rigid couplings thus act as the silent guarantor of repeatable positioning and consistent surface finish in precision machining.

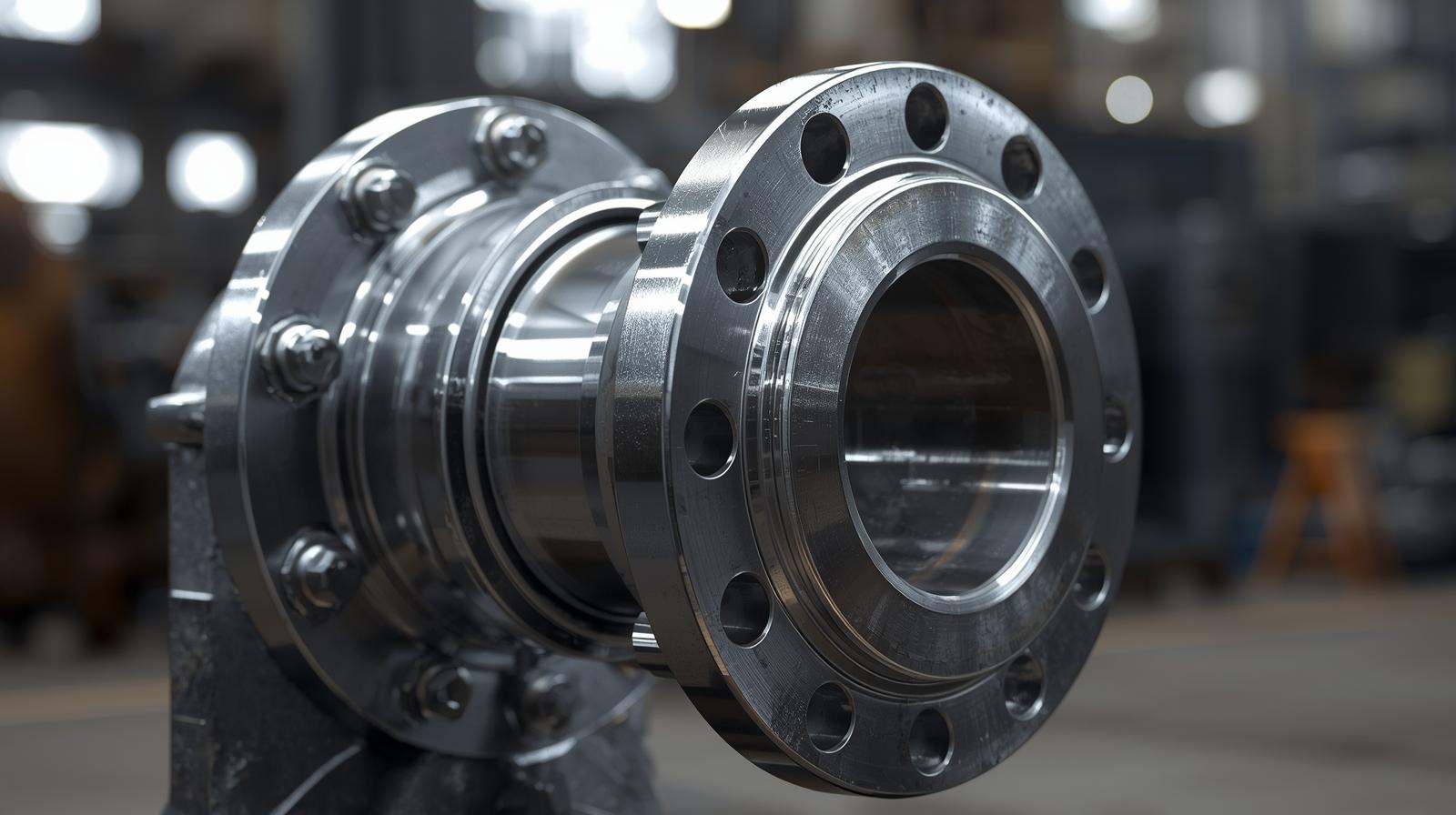

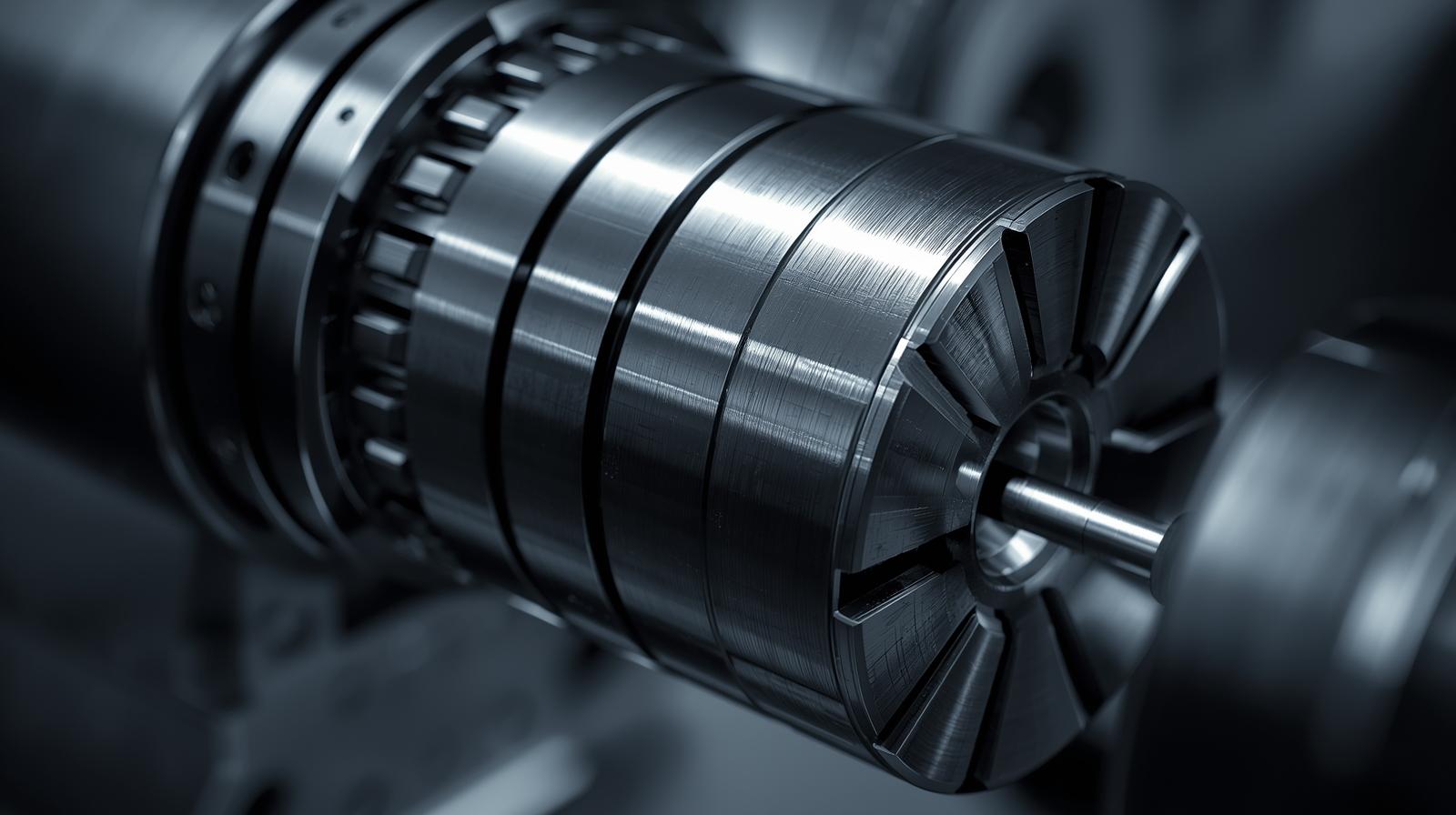

Built for Stability: Inside Dingjian’s Coupling Design

CNC environments demand more than torque transmission — they require structural uniformity and vibration control.

Dingjian’s rigid couplings are designed with optimized hub geometry and balanced clamp distribution to eliminate imbalance during high-speed motion.

Technical design features include:

-

H7/h6 bore tolerance: exact fit between motor and screw shafts.

-

Dynamic balance level ISO G2.5: supports speeds up to 10,000 RPM.

-

Material flexibility: aluminum for lightweight spindles, alloy steel for heavy cutting loads.

-

Dual-clamp configuration: ensures symmetrical pressure and shaft alignment.

-

Surface hardness: HRC 30–36 for long-term wear resistance.

These characteristics help CNC systems maintain spindle concentricity and cutting consistency under dynamic torque.

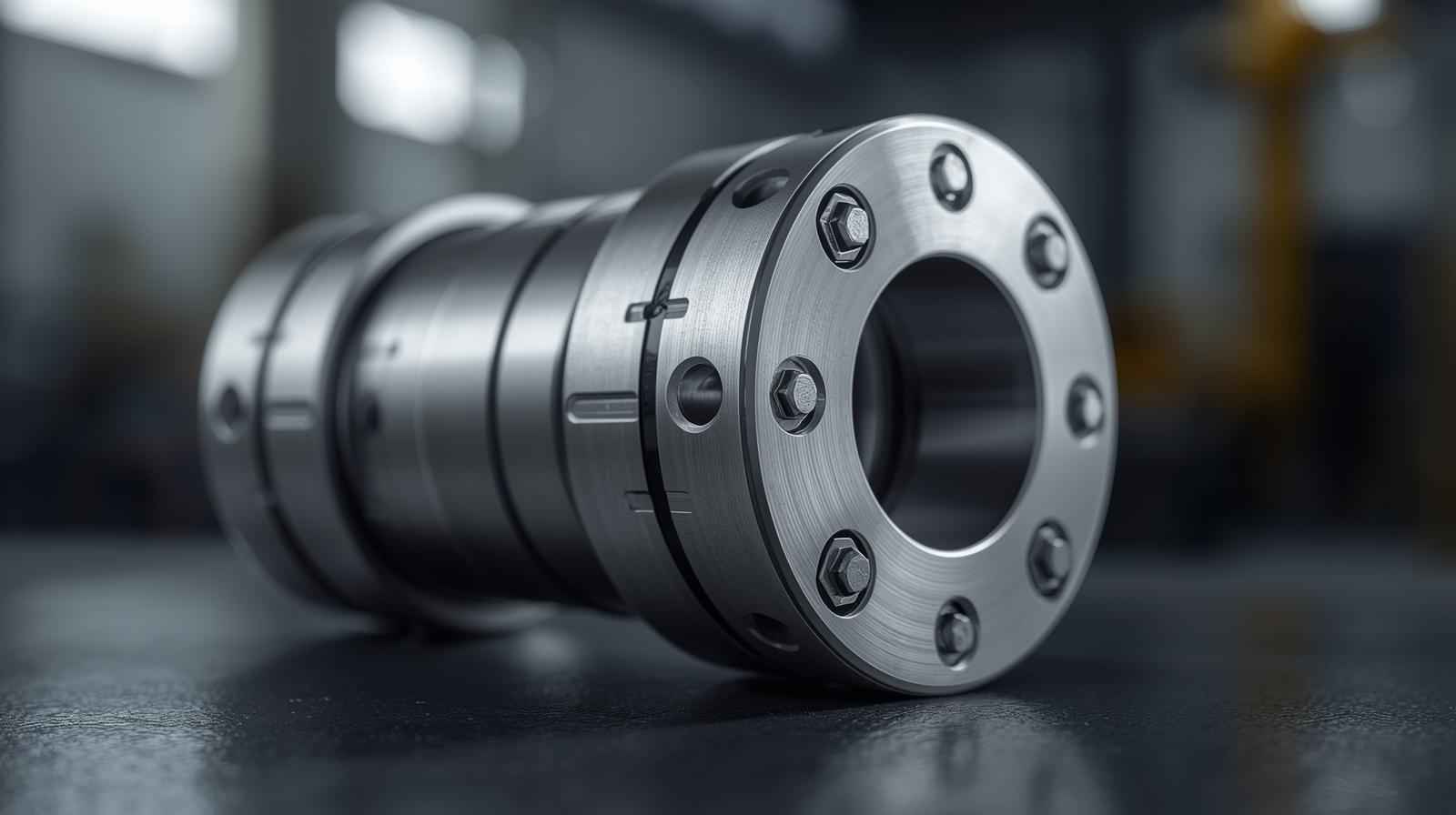

Controlled Precision Through Manufacturing Accuracy

Each Dingjian coupling is produced using a single-setup machining sequence to prevent cumulative tolerance errors.

-

Forged Material Preparation: Alloy steel or 7075-T6 aluminum for strength-to-weight optimization.

-

CNC Turning & Boring: Concentricity ≤0.01 mm for high-speed spindle compatibility.

-

Clamp Slot Milling: Uniform force distribution for secure torque hold.

-

Balancing & Inspection: Every coupling is dynamically tested before delivery.

-

Protective Coating: Black oxide or anodized finish enhances corrosion resistance.

This production discipline guarantees repeatable quality, critical for OEM CNC machinery suppliers and automation system integrators.

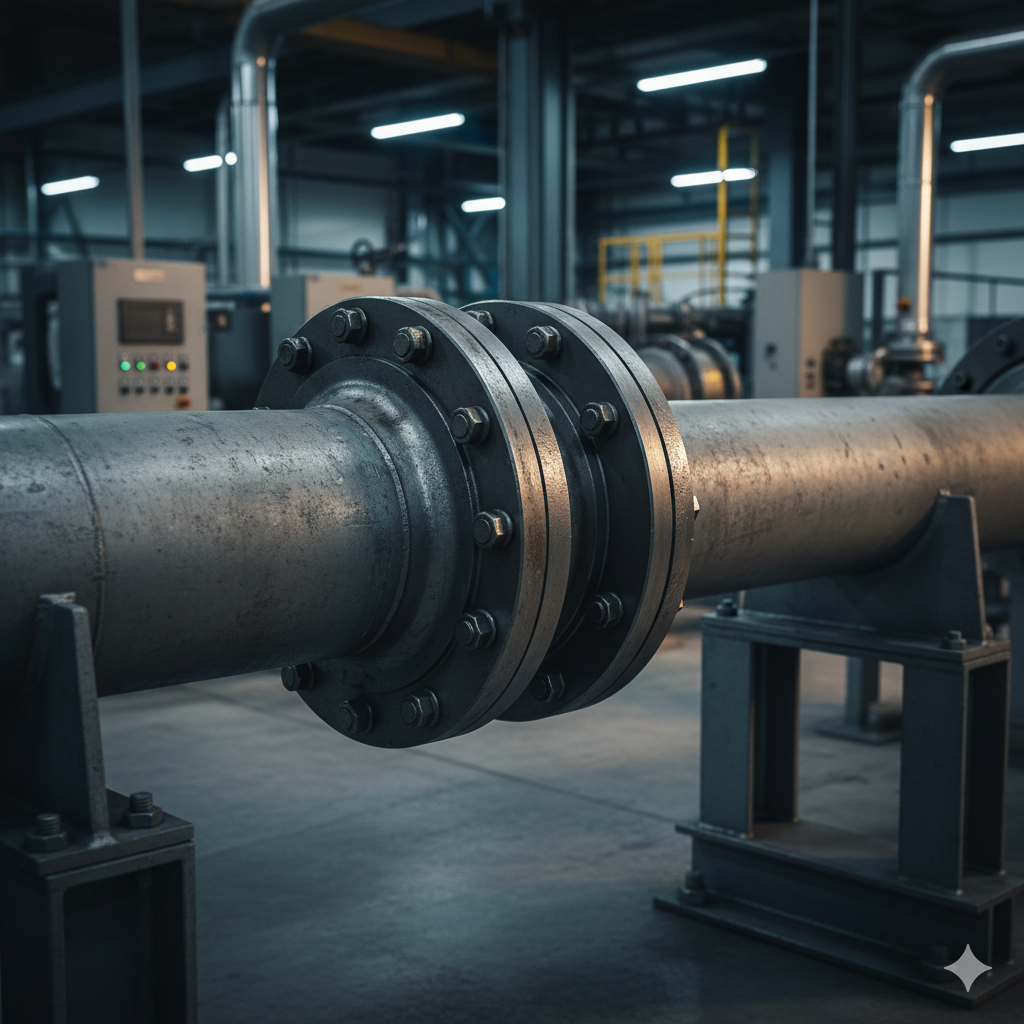

Performance Reliability Across CNC Applications

| CNC Type | Coupling Configuration | Core Function |

|---|---|---|

| Vertical Machining Center (VMC) | Steel solid coupling | High torque and rigidity for heavy cuts |

| Horizontal Machining Center (HMC) | Flanged rigid coupling | Balanced torque transfer under high inertia |

| CNC Lathe | Compact aluminum coupling | Smooth acceleration and low inertia |

| 5-Axis Machine | Balanced dual-clamp coupling | Multi-axis synchronization and zero backlash |

| CNC Grinding Machine | Short hub rigid coupling | Micron-level accuracy, low vibration |

By aligning coupling material and geometry to machine function, Dingjian ensures each product enhances both spindle life and cutting consistency.

Choosing the Right Rigid Coupling for CNC Drives

| Operating Condition | Recommended Type | Focus Area |

|---|---|---|

| High-Speed, Low Torque | Aluminum clamp coupling | Lightweight and balanced motion |

| Heavy Cutting Operations | Steel rigid coupling | Maximum stiffness, stable torque flow |

| Compact Spindle Assemblies | Short-bore model | Saves space without reducing strength |

| Frequent Tool Changes | Split-hub configuration | Quick disassembly and realignment |

| Temperature-Variable Environments | Coated steel type | Maintains alignment under thermal change |

Practical Tip:

Always confirm shaft parallelism and preload settings during installation — even a 0.02 mm offset can reduce tool accuracy and accelerate bearing wear.

Common Questions from CNC System Users

Q1: Why use a rigid coupling instead of an elastic one in CNC machines?

Because precision CNC applications demand zero backlash; rigid couplings ensure perfect torque synchronization.

Q2: What’s the best material choice for high-speed applications?

Aluminum couplings with dynamic balance (ISO G2.5) minimize inertia and vibration.

Q3: How does Dingjian ensure torque stability at 10,000 RPM?

Each unit undergoes dynamic balancing and concentricity testing to remove rotational deviation.

Q4: Can Dingjian supply OEM versions for CNC machine builders?

Yes. Bore dimensions, hub geometry, and surface finishes can be tailored for OEM integration.

Precision That Defines Performance

In CNC machining, precision starts at the power link — the coupling that binds motion and control together.

Dingjian’s rigid couplings for CNC machines combine dimensional accuracy, material strength, and vibration balance to support high-speed cutting and repeatable performance.

To request technical specifications or OEM customization, visit the official homepage or reach us through the contact page.