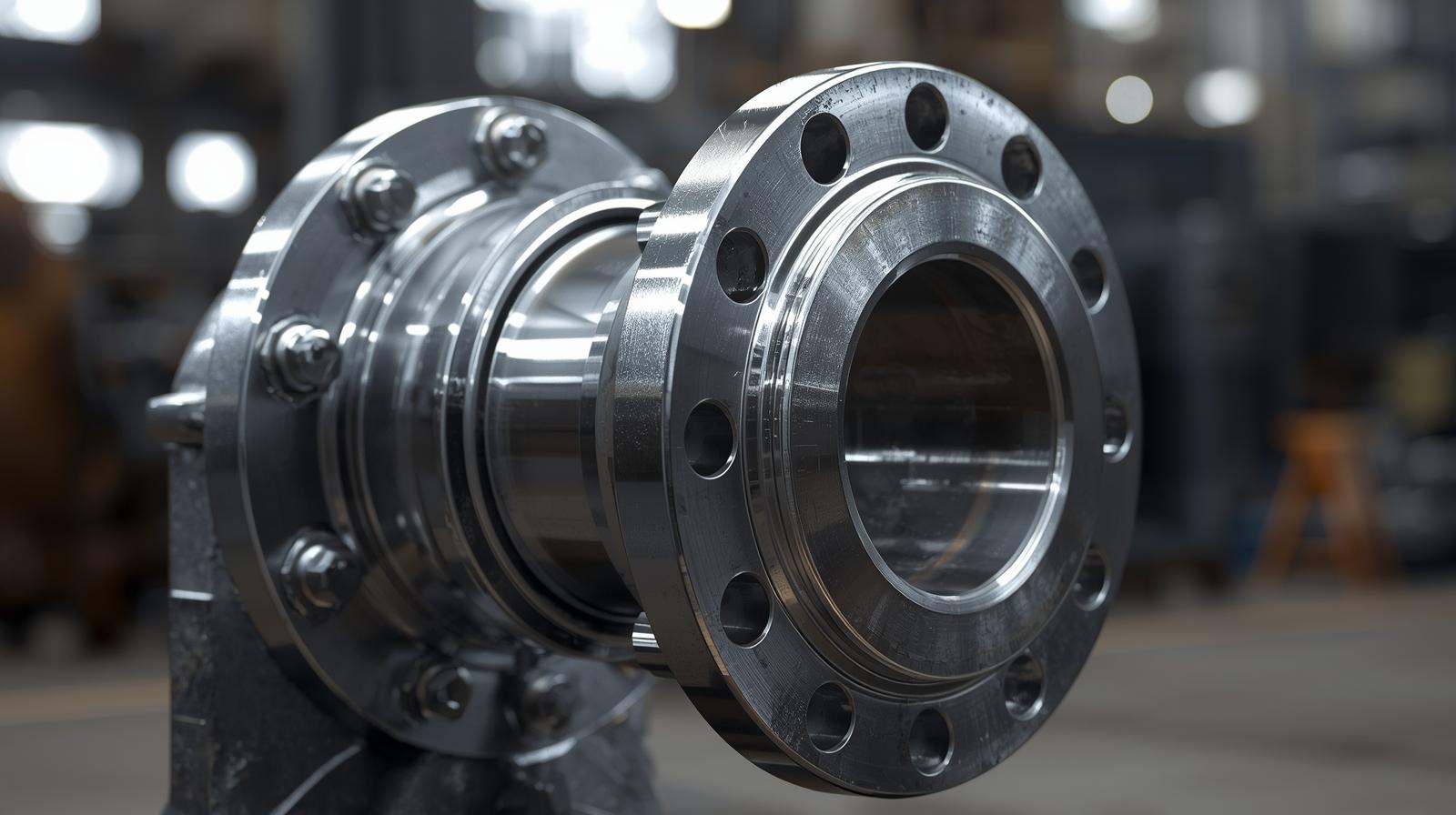

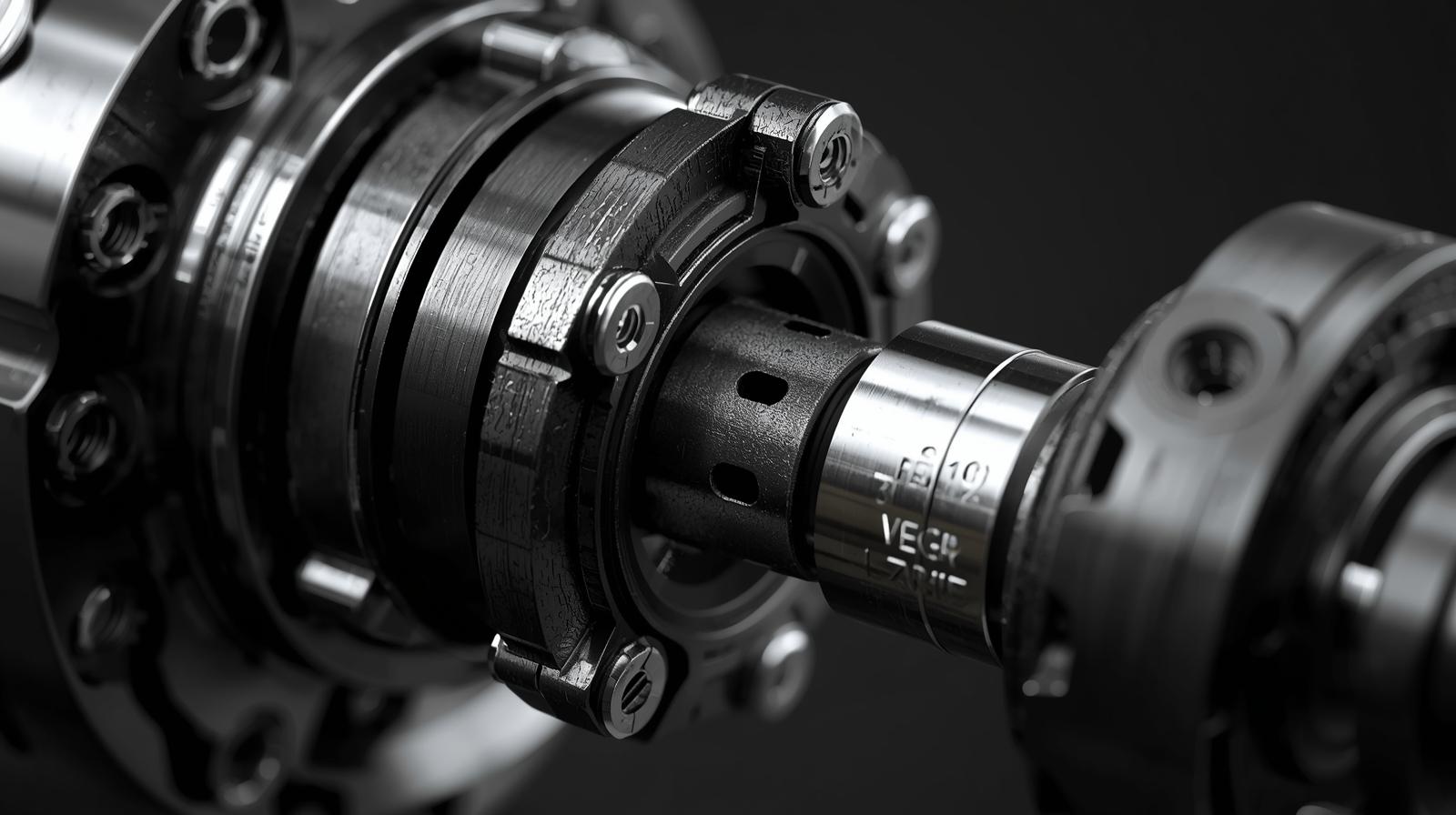

Heavy Duty Rigid Coupling OEM: Built for Torque, Stability, and Longevity

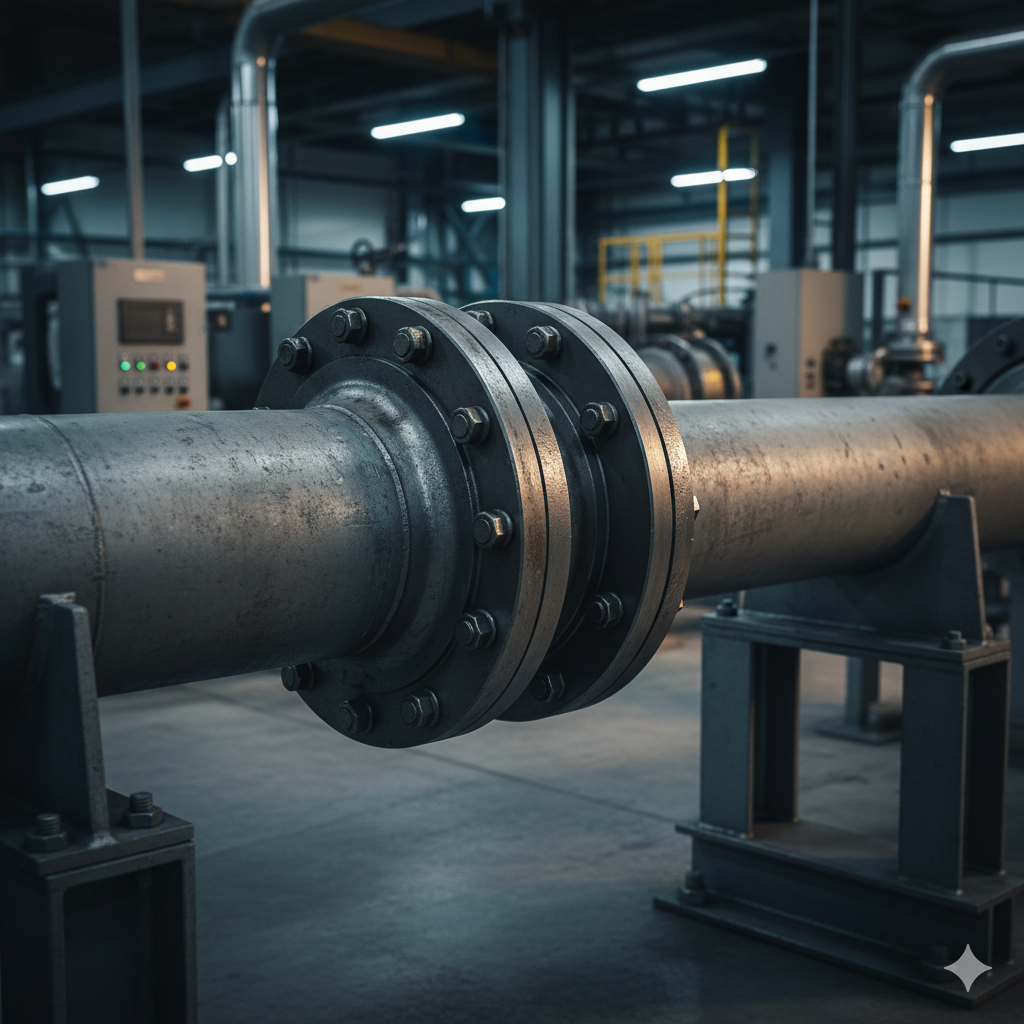

In industries where production never stops—steel rolling, mining, power generation—mechanical stability becomes the invisible measure of success.

A single coupling failure can halt an entire operation, costing hours of downtime and energy waste.

This is why heavy-duty rigid couplings, with their pure torque path and structural solidity, remain the preferred choice for continuous, high-power transmission systems.

Dingjian, as a trusted OEM supplier, delivers coupling solutions that sustain massive torque without compromising precision or service life.

The Physics of Rigidity: How Structure Controls Torque

A rigid coupling behaves as a single mechanical body, uniting two shafts so tightly that any torsional flex is eliminated.

This structural continuity ensures the same rotational speed, alignment, and torque delivery on both sides of the drive system.

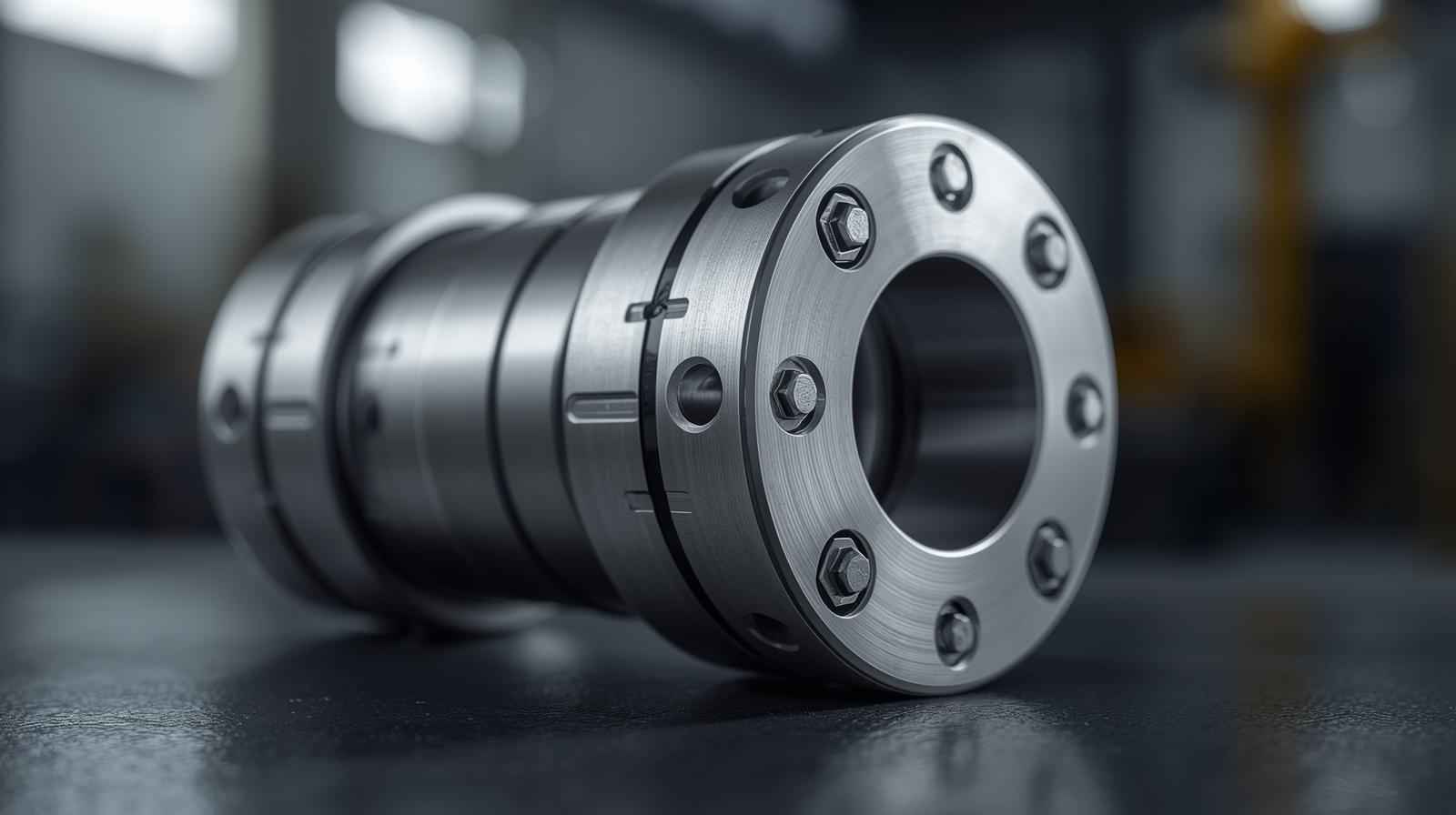

Design Essentials:

-

Full-surface shaft contact reduces micro-movement and slippage

-

Optimized wall thickness maintains shape under load stress

-

Controlled bolt preloads ensure concentric clamping without deformation

-

Heat-resistant geometry maintains alignment during continuous operation

Such design choices allow rigid couplings to transmit torque efficiently in mills, crushers, turbines, and lifting systems, where high inertia and impact forces are routine.

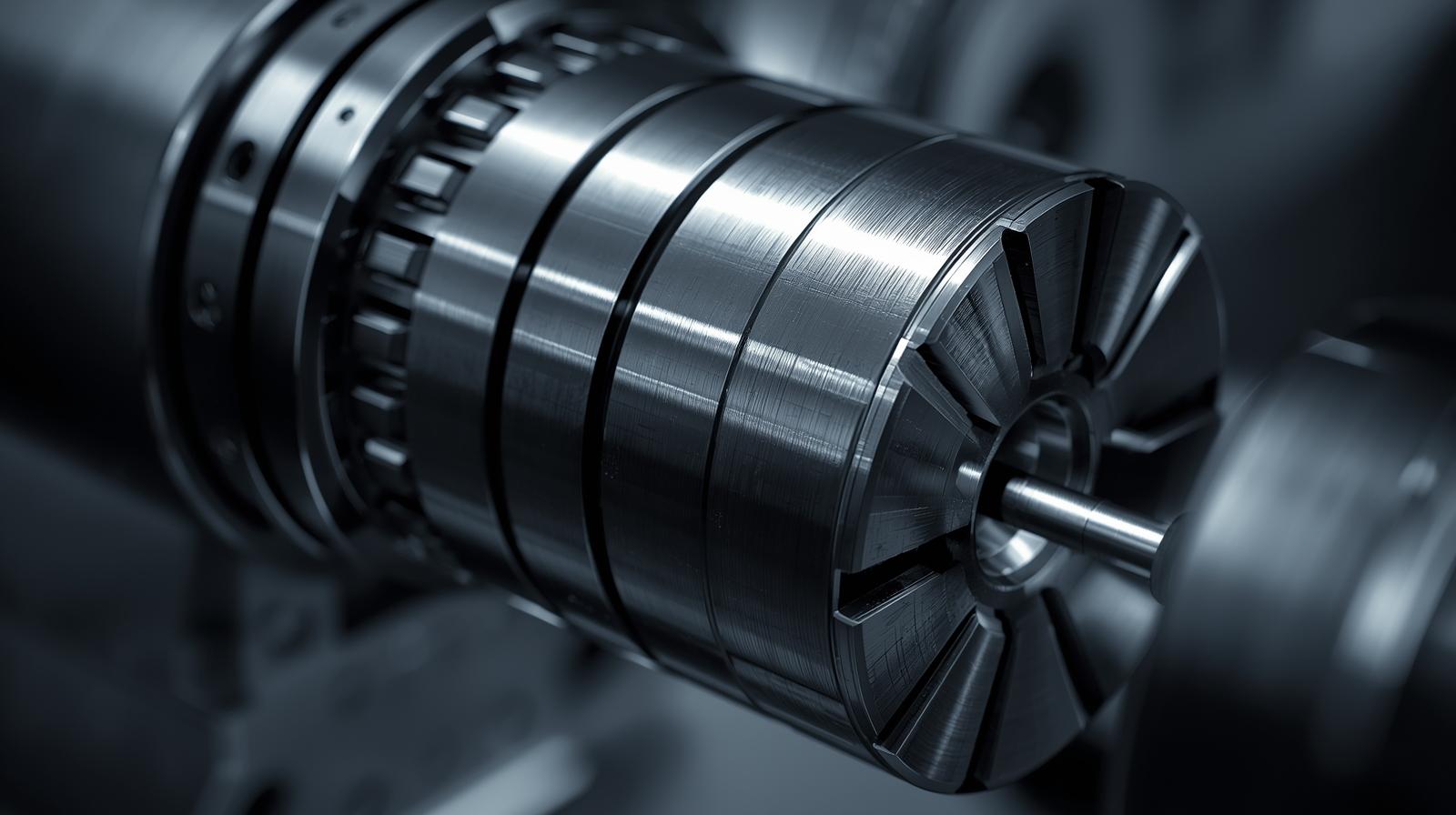

From Forging to Precision Fit: The Manufacturing Journey

Dingjian’s OEM process begins with metallurgy and ends with precision.

Each coupling is not just machined—it’s calibrated to match the torque signature of the application.

-

Material Preparation – Forged 42CrMo and 40CrNiMo steels undergo grain refinement for durability.

-

CNC Machining – Single-setup turning achieves coaxial tolerance within ±0.015 mm.

-

Heat Treatment & Stress Relief – Optimizes hardness and elasticity balance for long-term use.

-

Torque Verification – Every coupling is tested at 125–150% of rated torque to validate stability.

-

Protective Coating – Black oxide or phosphate finish ensures resistance to corrosion and oil exposure.

Each stage ensures dimensional integrity and performance uniformity across high-volume OEM production runs.

Endurance Under Pressure: What Sets Heavy-Duty Models Apart

| Property | Standard Coupling | Dingjian Heavy-Duty OEM Type |

|---|---|---|

| Torque Load Capacity | ≤150% rated torque | ≥300% rated torque |

| Hub Material | Medium carbon steel | Alloy steel (42CrMo / 40CrNiMo) |

| Bore Range | ≤80 mm | Up to 320 mm |

| Balance Accuracy | ISO G6.3 | ISO G2.5 |

| Continuous Service Life | 10,000 hrs | 25,000+ hrs |

The performance margin is achieved not by size, but by metallurgical refinement and load-path optimization, enabling Dingjian’s couplings to perform under cyclic torque and axial vibration for years without readjustment.

Where Torque Meets Longevity: Industry-Specific Demands

| Sector | Typical Equipment | Operating Challenge |

|---|---|---|

| Steel & Metallurgy | Rolling mills, presses | Continuous torque and heat exposure |

| Mining | Crushers, conveyors | Sudden load impacts and abrasive dust |

| Power Generation | Turbines, pumps | Long-term thermal stability |

| Cement Production | Mixers, rotary kilns | Constant vibration and fine-particle wear |

| Marine Systems | Winches, propulsion drives | Corrosion and vibration in salt air |

Each project begins with analyzing load profiles, torque range, and environmental factors—Dingjian’s OEM design process ensures application-specific performance rather than off-the-shelf fit.

Coupling Selection Framework: Balancing Power, Space, and Maintenance

| Use Case | Recommended Model | Key Focus |

|---|---|---|

| High Static Torque Drives | Solid forged rigid type | Maximum torsional rigidity |

| Shock-Load Machinery | Reinforced flanged model | Impact absorption through geometry |

| Outdoor / Marine Equipment | Stainless version | Surface integrity and corrosion resistance |

| Compact Machinery | Short-hub version | Reduced installation footprint |

| Maintenance-Heavy Systems | Split-hub configuration | Easy access and reassembly |

Before choosing a coupling, OEM designers should assess:

-

Torque peaks vs. continuous load

-

Shaft alignment tolerance (radial & angular)

-

Bearing spacing and allowable deflection

-

Service cycle and lubrication schedule

Dingjian assists OEM clients in fine-tuning these parameters through 3D modeling and torque mapping to ensure optimal integration.

Technical Insights from OEM Users

Q1: How does a heavy-duty coupling handle overloads?

Dingjian designs include material safety margins up to 2.5× rated torque, maintaining structural stability under short-term overload.

Q2: Can designs be adapted to match foreign standards?

Yes. Dimensions, fasteners, and flange geometry can be adjusted for ISO, DIN, or ANSI system compatibility.

Q3: How often should couplings be rebalanced or serviced?

Typically, no rebalancing is needed within 25,000 hours if installed with correct alignment and bolt preload.

Q4: What type of coating is recommended for humid environments?

Phosphate or nickel-plated finishes perform best for plants in coastal or chemical areas.

Precision That Sustains Industry

Every heavy-duty rigid coupling represents more than mechanical connection—it’s the safeguard of operational continuity.

By combining precision machining, stable metallurgy, and OEM-level customization, Dingjian helps global industries achieve lasting power transmission with minimal downtime.

To explore customization options or request specifications, visit the official homepage or reach us via the contact page.