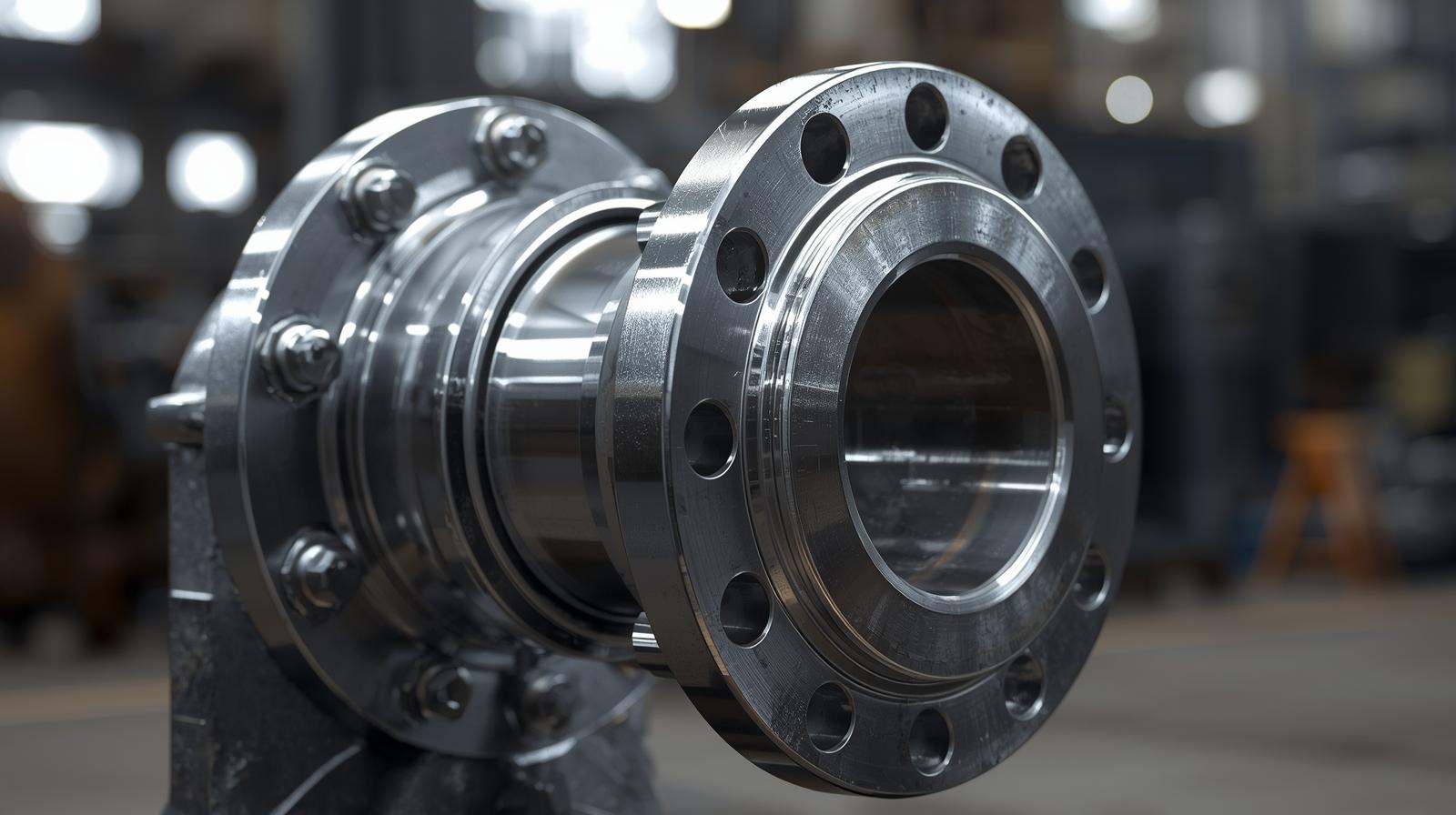

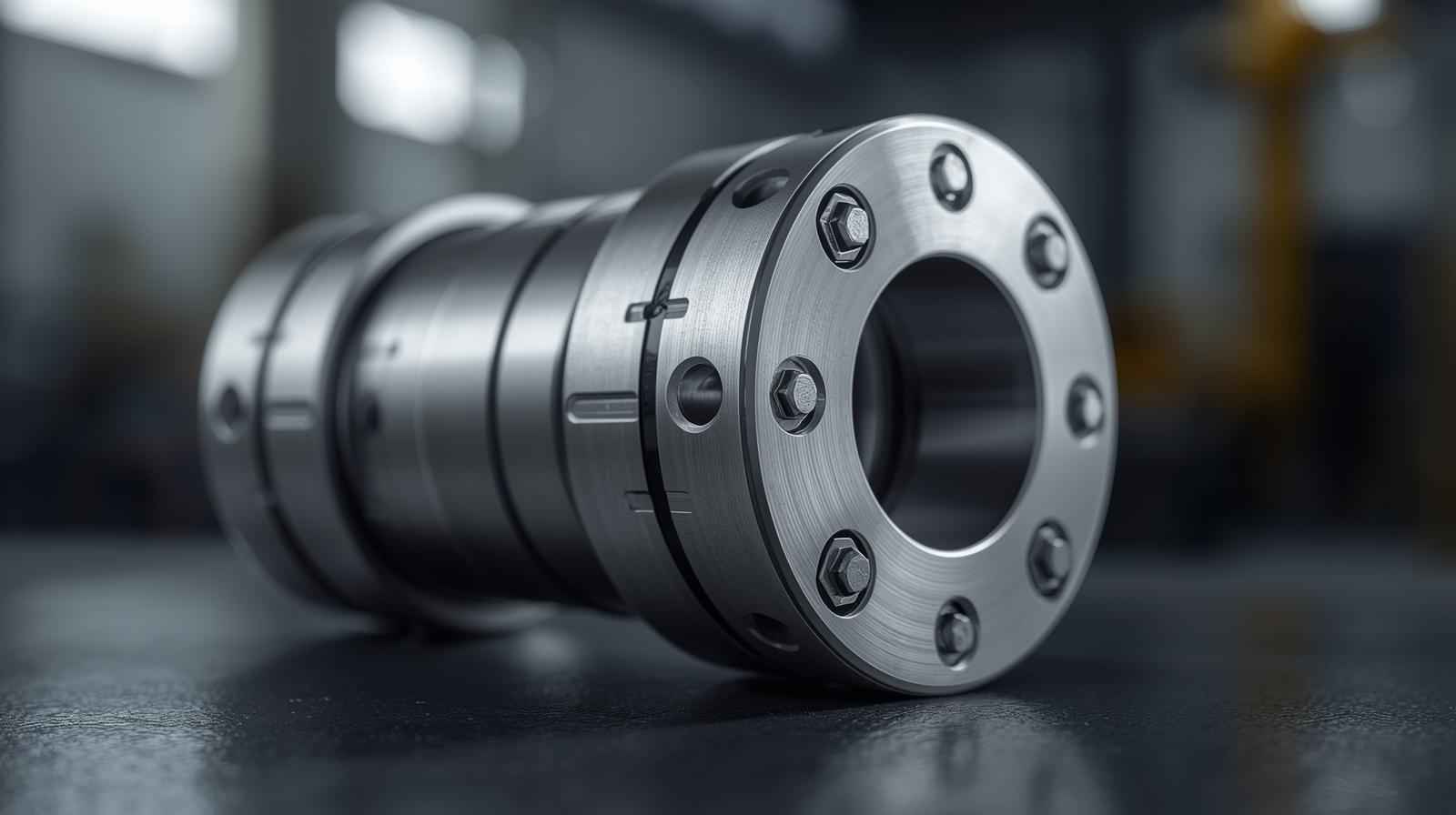

Precision Rigid Coupling for Motor Shaft: Achieving Perfect Alignment in Motion Control

In servo-driven automation and CNC systems, motion precision depends on how perfectly the motor transfers torque to the driven component.

A rigid coupling acts as the direct bridge between the motor and the load — and when every micron matters, even the slightest shaft offset can impact performance.

That’s why Dingjian designs precision rigid couplings for motor shafts that guarantee zero backlash, perfect alignment, and superior rotational accuracy across thousands of operation cycles.

Why Motor Shafts Require True Rigid Precision

Servo motors, stepper motors, and spindle drives operate with high acceleration and deceleration rates.

Under these conditions, flexible couplings can introduce micro-delays and backlash, causing positional error.

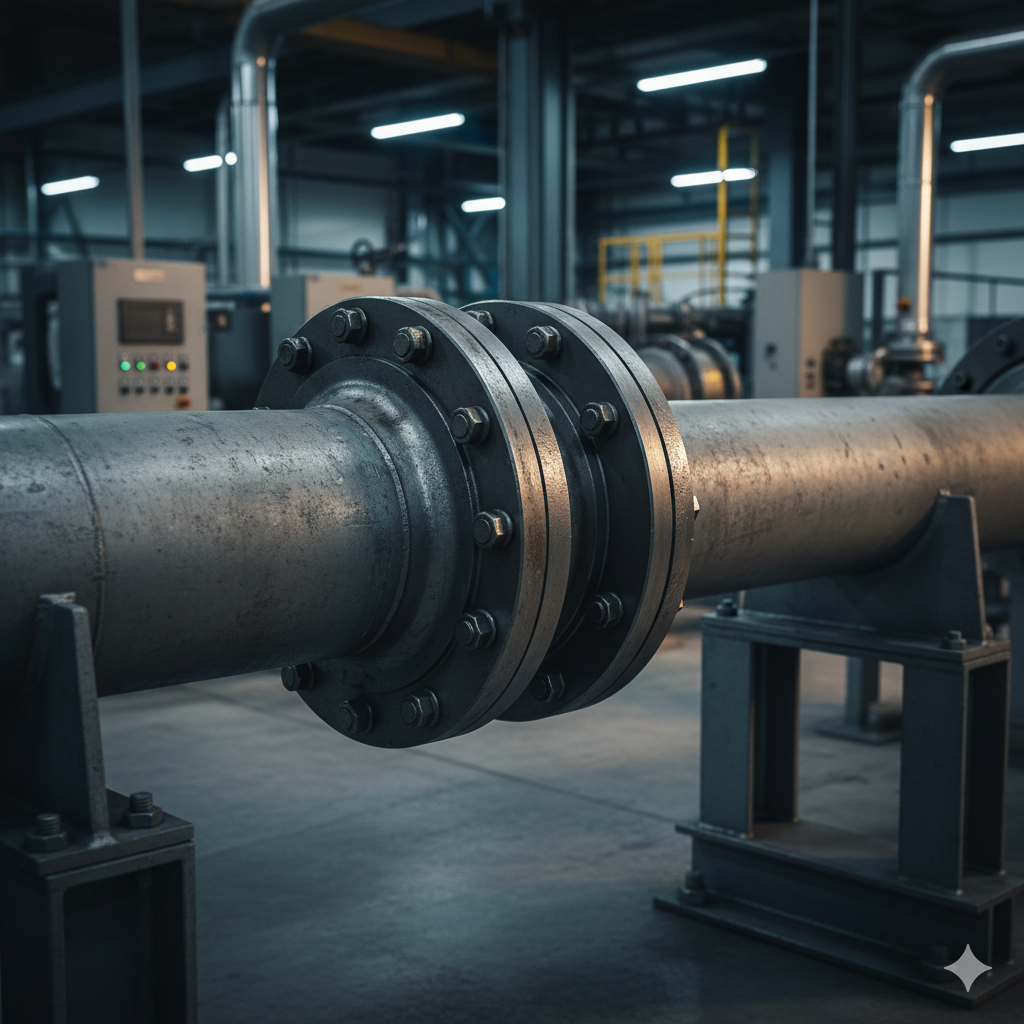

Rigid couplings eliminate that by forming a solid mechanical link between shafts.

Core functional advantages:

-

Zero torsional play for accurate position feedback

-

Uniform torque distribution through interference fit

-

Reduced vibration and heat during high-speed rotation

-

Stable alignment during long duty cycles

In high-speed automation, precision coupling isn’t optional — it’s part of the accuracy guarantee.

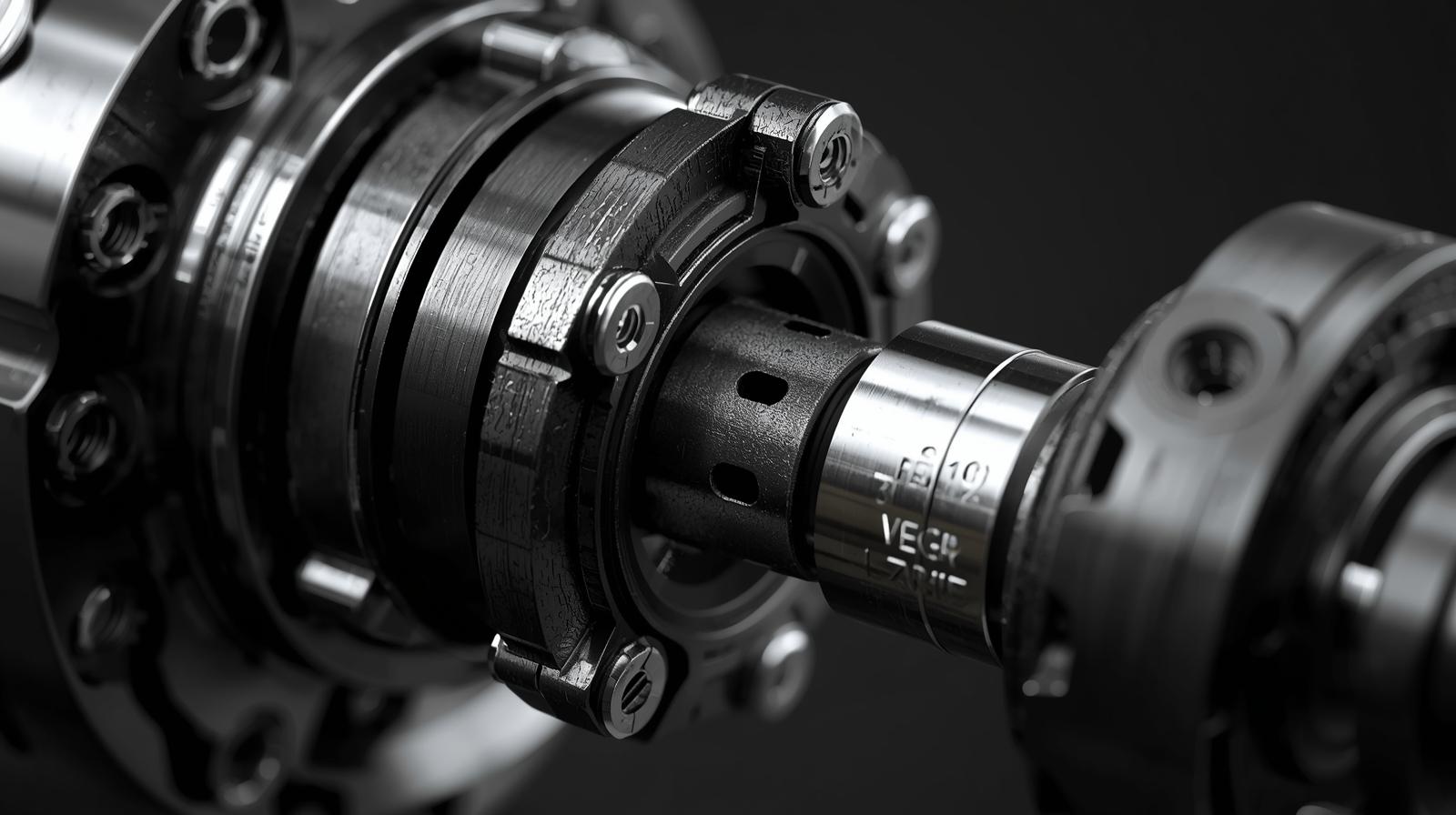

Precision from Design: Structural Features That Matter

A rigid coupling’s performance depends on its geometry and clamping uniformity.

Dingjian’s couplings are designed using 3D tolerance simulation to ensure each component maintains coaxial balance and symmetric torque flow.

Key design characteristics:

-

Dual-clamp or set-screw configuration: ensures complete contact and high torque capacity.

-

H7/h6 bore tolerance: guarantees a perfect shaft fit without damage.

-

Surface roughness ≤ Ra0.8: minimizes friction during torque transmission.

-

Dynamic balancing to ISO G2.5: eliminates vibration at speeds up to 10,000 RPM.

These features make Dingjian’s precision couplings suitable for robotics, servo drives, linear actuators, and test instruments, where torque uniformity and responsiveness are critical.

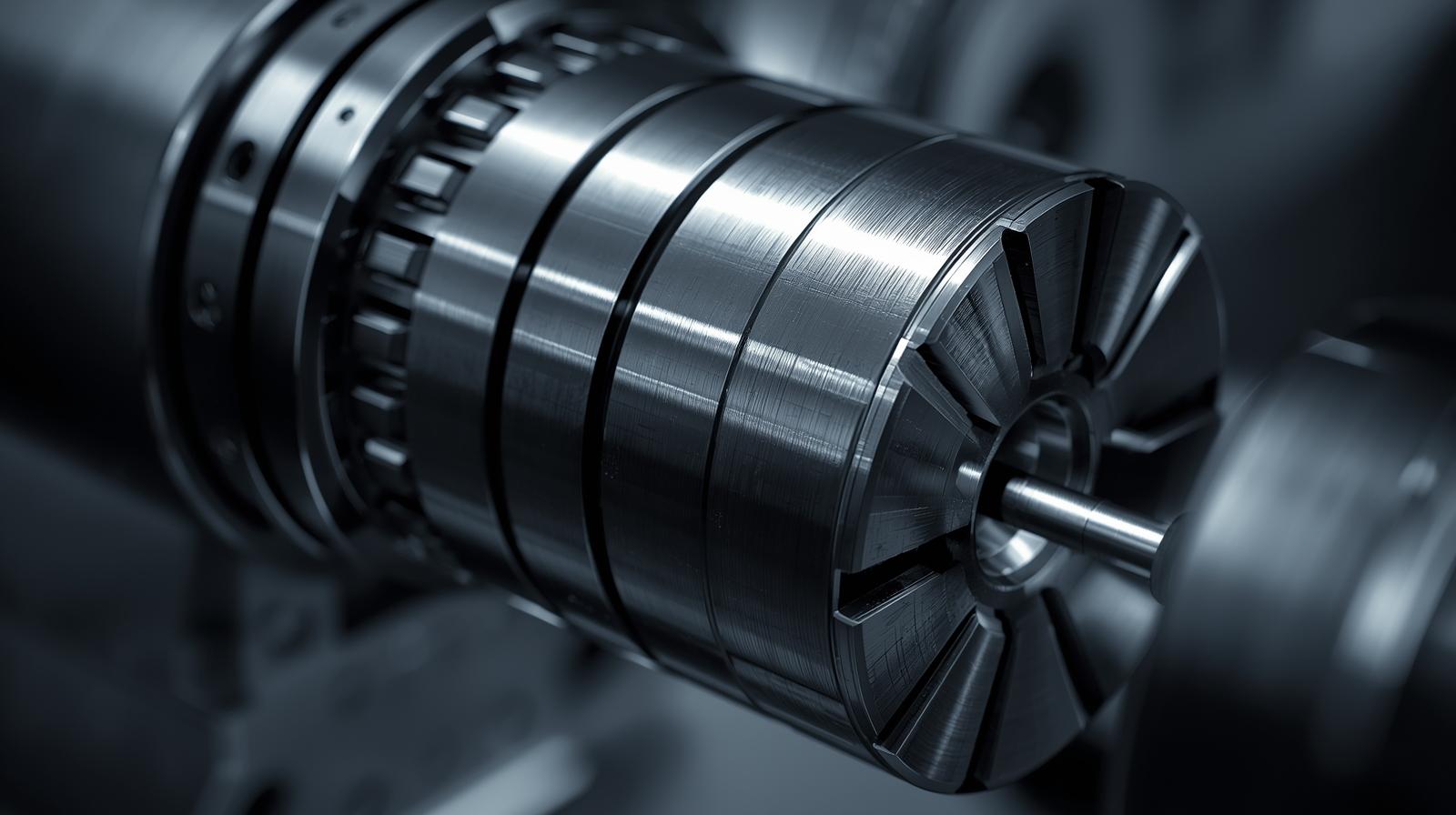

Manufacturing Process: From Alloy to Alignment

Producing a precision-grade coupling involves tight machining control and material selection.

Each Dingjian unit goes through a multi-stage production sequence designed to maintain dimensional integrity and rotational balance.

-

Material Selection: High-grade aluminum alloy or 42CrMo steel for lightweight or heavy-torque applications.

-

CNC Turning & Boring: Ensures concentricity ≤0.01 mm for motor-to-load alignment.

-

Keyway & Clamp Slot Machining: Custom options for servo or spindle motor interfaces.

-

Balancing & Polishing: Dynamic tests to control inertia and eliminate radial runout.

-

Surface Protection: Anodized or phosphate coatings improve corrosion and wear resistance.

This process ensures that Dingjian’s precision couplings maintain consistent alignment — even after extended operation in high-frequency cycles.

Maintaining Positional Accuracy Across Industries

| Application Field | Motor Type | Core Requirement |

|---|---|---|

| CNC Machinery | Servo / Spindle | Zero backlash and stability at high speed |

| Automation Lines | Stepper motors | Smooth torque delivery and quick acceleration |

| Robotics | Compact servo systems | Lightweight coupling with high stiffness |

| Testing & Measurement | Precision motors | Micron-level torque repeatability |

| Medical Equipment | Micro-drive motors | Silent operation and minimal vibration |

Across industries, Dingjian’s couplings help ensure mechanical repeatability, allowing control systems to maintain accurate motion feedback and reduced positional drift.

Matching Coupling Type to Motor Application

| Drive Condition | Recommended Coupling | Performance Benefit |

|---|---|---|

| High-Speed Rotation | Aluminum clamp-type rigid coupling | Lightweight, balanced operation |

| High Torque Transmission | Steel solid-type coupling | Strong torsional stiffness |

| Frequent Start/Stop Cycles | Split-hub rigid coupling | Quick installation, zero misalignment |

| Confined Motor Assemblies | Short-bore compact design | Saves axial space |

| Sensitive Positioning Systems | Balanced dual-clamp version | Eliminates backlash and micro-slip |

When selecting a coupling, key considerations include shaft fit, torque load, inertia ratio, and allowable misalignment.

Dingjian provides customization for bore diameters, slot shapes, and balancing standards to ensure full motor compatibility.

Frequently Asked Questions

Q1: Can precision rigid couplings be used with stepper motors?

Yes, provided that shaft alignment is exact. Stepper systems benefit from the zero backlash and high stiffness.

Q2: What’s the typical bore tolerance for Dingjian’s motor couplings?

All units maintain H7/h6 tolerance with concentricity ≤0.01 mm.

Q3: Are custom surface finishes available?

Yes, anodizing (for aluminum) and black oxide (for steel) finishes can be applied based on environment.

Q4: How often should these couplings be reinstalled or inspected?

Visual inspections every 5,000 hours are sufficient unless subjected to overload or vibration anomalies.

Delivering Precision That Drives Motion

In motion control, the quality of a coupling defines the accuracy of the entire system.

Dingjian’s precision rigid couplings transform torque delivery into predictable, repeatable motion — ensuring that every rotation of the motor translates directly into controlled movement.

For detailed specifications or custom motor-shaft coupling designs, visit the official homepage or reach the team through the contact page.