Industrial Flange Coupling Manufacturer: Precision Connection for Heavy-Duty Power Systems

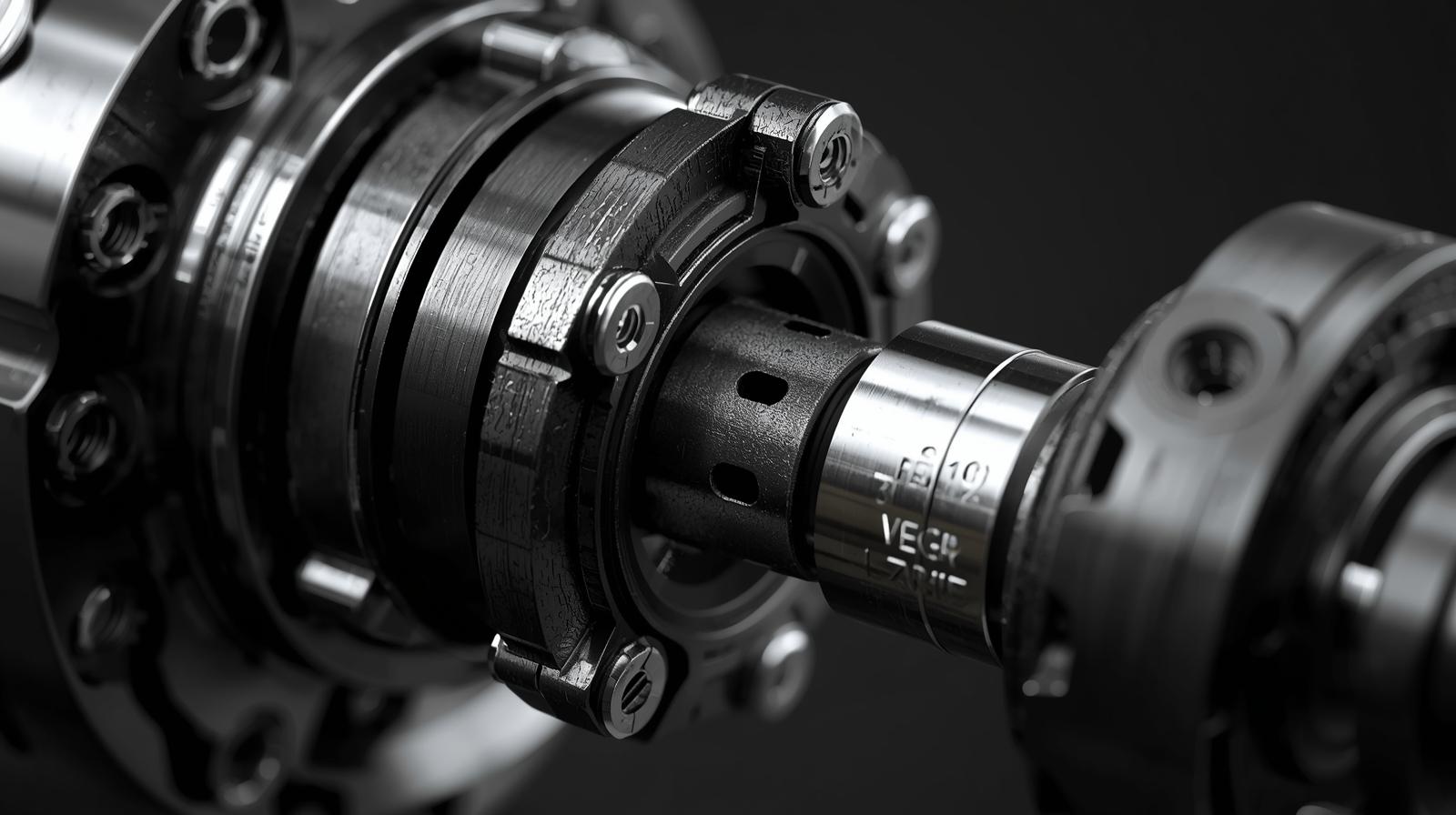

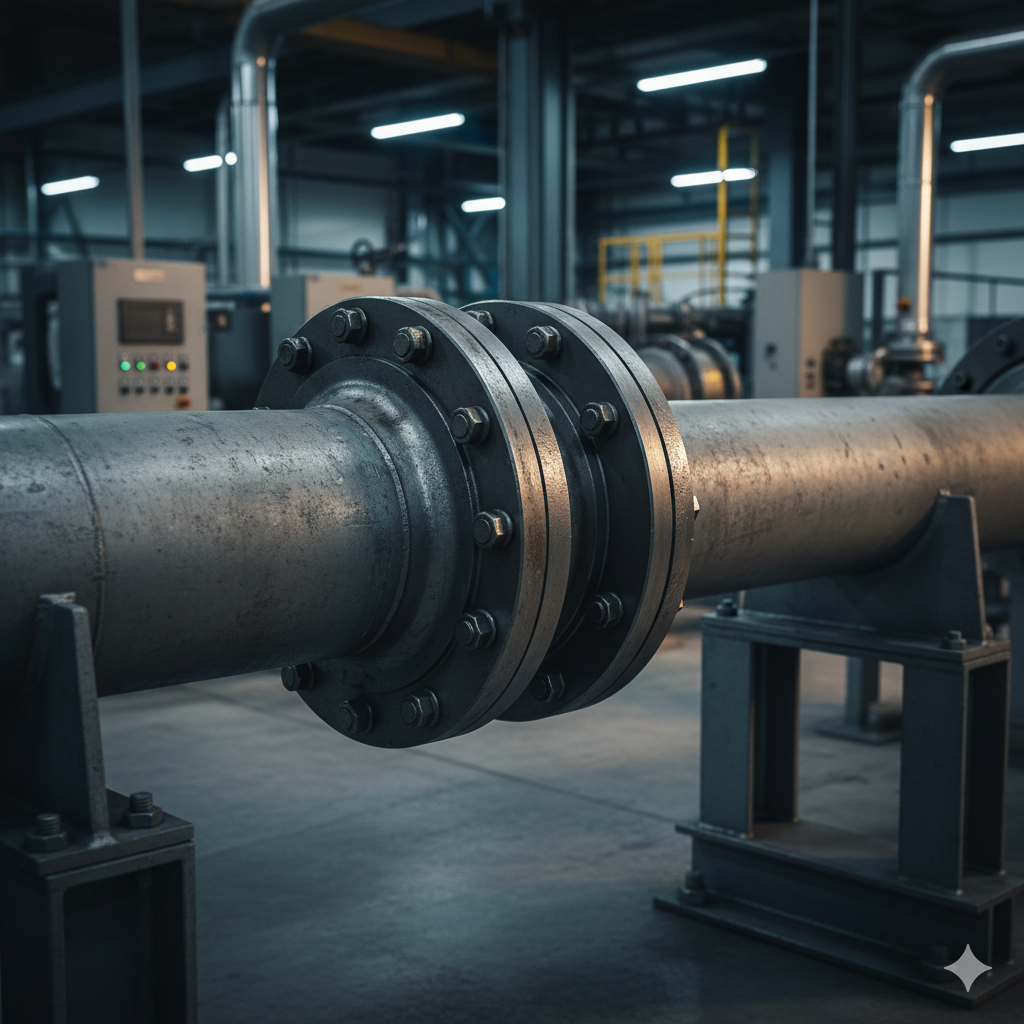

In every high-torque industrial system—rolling mills, turbines, crushers—the coupling is more than a connector; it’s the point where mechanical strength meets precision alignment.

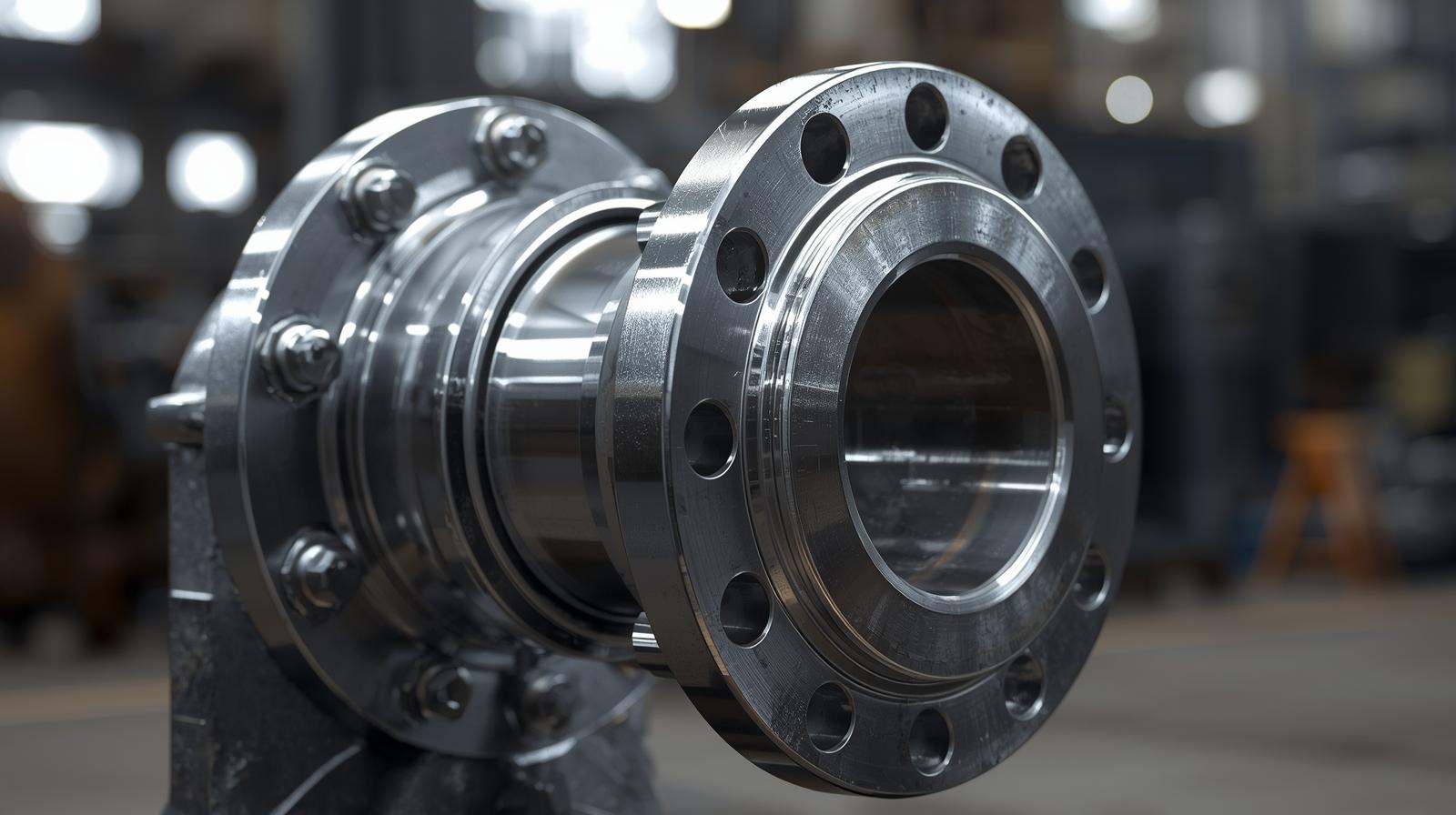

The flange coupling, with its bolted disc connection and high rigidity, remains one of the most trusted designs in heavy-duty transmission.

As a long-term industrial flange coupling manufacturer, Dingjian focuses on delivering couplings that maintain torque balance and structural integrity under years of continuous operation.

How the Flange Structure Transfers Power Without Loss

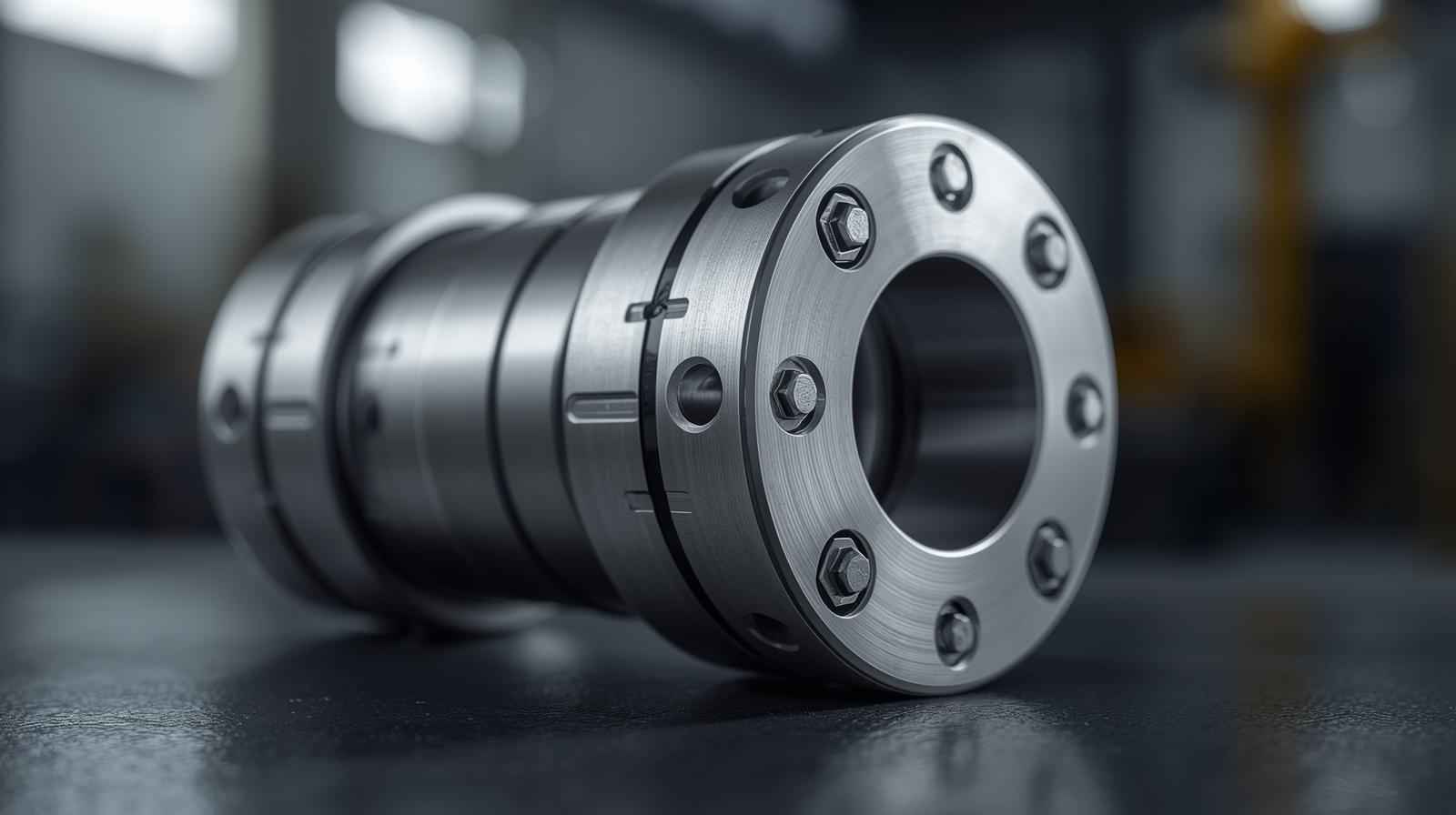

A flange coupling connects two aligned shafts through interlocked flanges and high-strength bolts.

This design ensures perfect synchronization between driving and driven shafts, achieving zero backlash torque transmission.

Core mechanical characteristics:

-

Bolted joint integrity: evenly distributed torque path across all bolts.

-

Full-face contact: prevents stress concentration and slippage.

-

High rigidity: suitable for steady-load transmission in critical systems.

-

Service simplicity: easy inspection and bolt retightening during maintenance.

These properties make flange couplings essential for high-power, slow-speed drives where torque accuracy outweighs flexibility.

Forged for Strength: The Dingjian Manufacturing Process

Producing a durable industrial coupling starts from metallurgical control and ends with assembly precision.

At Dingjian, each flange coupling is forged, machined, and balanced according to international quality standards.

Manufacturing workflow:

-

Material Preparation: High-grade alloy steels (42CrMo, 40Cr) with verified mechanical properties.

-

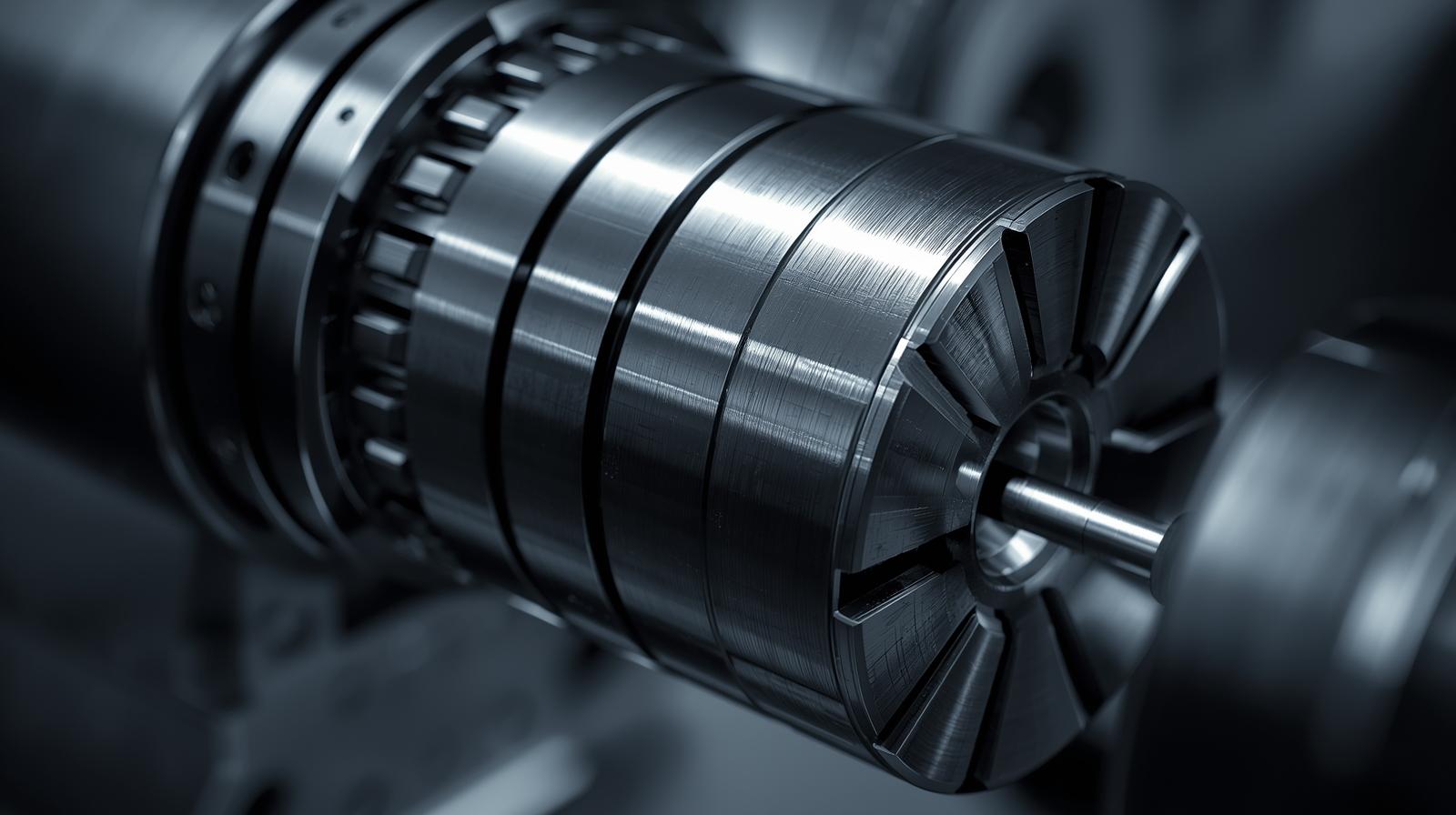

Closed-Die Forging: Enhances grain flow for superior strength and fatigue resistance.

-

Precision CNC Machining: Achieves face flatness ≤0.02 mm and bore concentricity within ±0.015 mm.

-

Bolt Hole Positioning: Computer-controlled drilling guarantees symmetrical torque distribution.

-

Dynamic Balancing: Calibrated to ISO G6.3 or better for vibration-free performance.

-

Protective Finishing: Phosphate or black oxide coatings protect against corrosion and oil mist.

This process ensures that every Dingjian flange coupling maintains tight fit, stable alignment, and long service reliability in industrial environments.

Torque Consistency and Structural Balance in Real Conditions

The performance of a flange coupling depends not just on its material but on how it behaves under repeated stress and variable torque.

Through simulation and on-machine validation, Dingjian evaluates each product for:

| Performance Metric | Dingjian Flange Coupling | Conventional Coupling |

|---|---|---|

| Torque Accuracy | ±1.5% deviation | ±5–8% deviation |

| Service Temperature | -40°C to +250°C | -20°C to +120°C |

| Maintenance Frequency | 1 per 10,000 hrs | 1 per 5,000 hrs |

| Structural Fatigue Life | 2× standard units | Standard life cycle |

This level of control guarantees consistent output even under conditions like temperature cycling, high vibration, or dust exposure.

Where Flange Couplings Excel: Industry Applications

| Sector | Example Equipment | Functional Focus |

|---|---|---|

| Steel & Rolling Mills | Drive spindles, gear reducers | Maintains torque integrity at high loads |

| Mining & Quarrying | Crushers, feeders | Resists impact and bending stress |

| Power Generation | Turbines, pumps | Withstands long-term heat and load cycles |

| Marine & Shipbuilding | Winches, deck cranes | Resists corrosion and fatigue |

| Cement Production | Mixers, rotary drives | Performs under vibration and dust ingress |

Each coupling model is designed to match the torque behavior and environment of the application, ensuring reliable power transmission across sectors.

Choosing the Right Flange Coupling for Industrial Use

| Installation Requirement | Recommended Model | Technical Consideration |

|---|---|---|

| Heavy Static Torque | Solid flange coupling | Full-face torque transfer |

| Shock or Vibration Loads | Reinforced bolted type | High-strength bolt preloads |

| Compact Assembly | Short-flange model | Saves installation space |

| High-Speed Operation | Balanced flange type | Prevents imbalance and shaft wear |

| Corrosive or Outdoor Use | Stainless or coated flange | Surface durability and low maintenance |

Before finalizing a selection, engineers should review:

-

Shaft alignment and parallelism tolerance

-

Expected torque peaks and start-up loads

-

Operating temperature range

-

Maintenance accessibility

Dingjian supports OEM and industrial users with 3D design assistance and torque mapping, ensuring optimal matching between coupling and machinery.

Common Questions from Industrial Buyers

Q1: What’s the main advantage of a forged flange coupling?

Forging improves material density and removes internal defects, increasing fatigue life by over 40%.

Q2: Can Dingjian supply couplings with custom bolt circles or flanges?

Yes, flange diameter, bolt size, and spacing can be customized per equipment specification.

Q3: How often should bolts be checked or replaced?

Regular inspections every 8,000–10,000 hours are sufficient for heavy-duty systems.

Q4: Are these couplings suitable for reversible drives?

Yes. The symmetrical bolt pattern supports bidirectional torque transfer.

Precision That Powers Industry

A flange coupling may look simple, but its reliability defines the uptime of entire production lines.

With forged strength, accurate machining, and long-term stability, Dingjian’s industrial flange couplings deliver the consistency demanded by heavy mechanical systems worldwide.

For technical consultation or OEM cooperation, visit the official homepage or contact our team via the contact page.