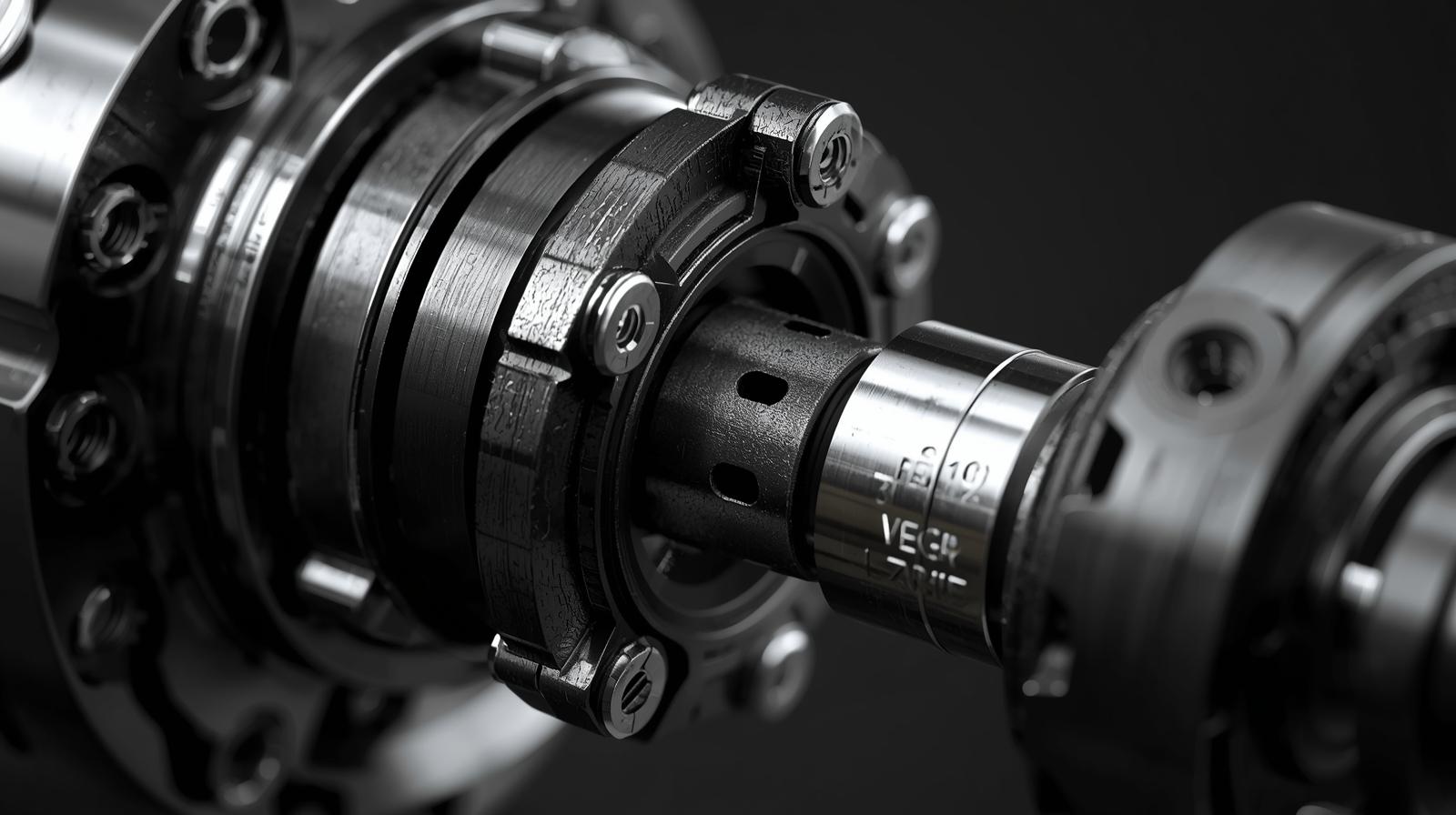

Custom Rigid Coupler Producer: Tailored Power Transmission for Demanding Machinery

In industrial automation and CNC systems, standard couplings often fail to meet the exact torque, bore, or alignment requirements of custom machines.

This is where custom rigid coupler producers like Dingjian come in — designing torque connectors that fit your system’s geometry, operating speed, and load demands.

A customized rigid coupler is not about luxury — it’s about ensuring every revolution of your drive system translates into precise, repeatable motion.

Why Customization Matters in Rigid Coupler Manufacturing

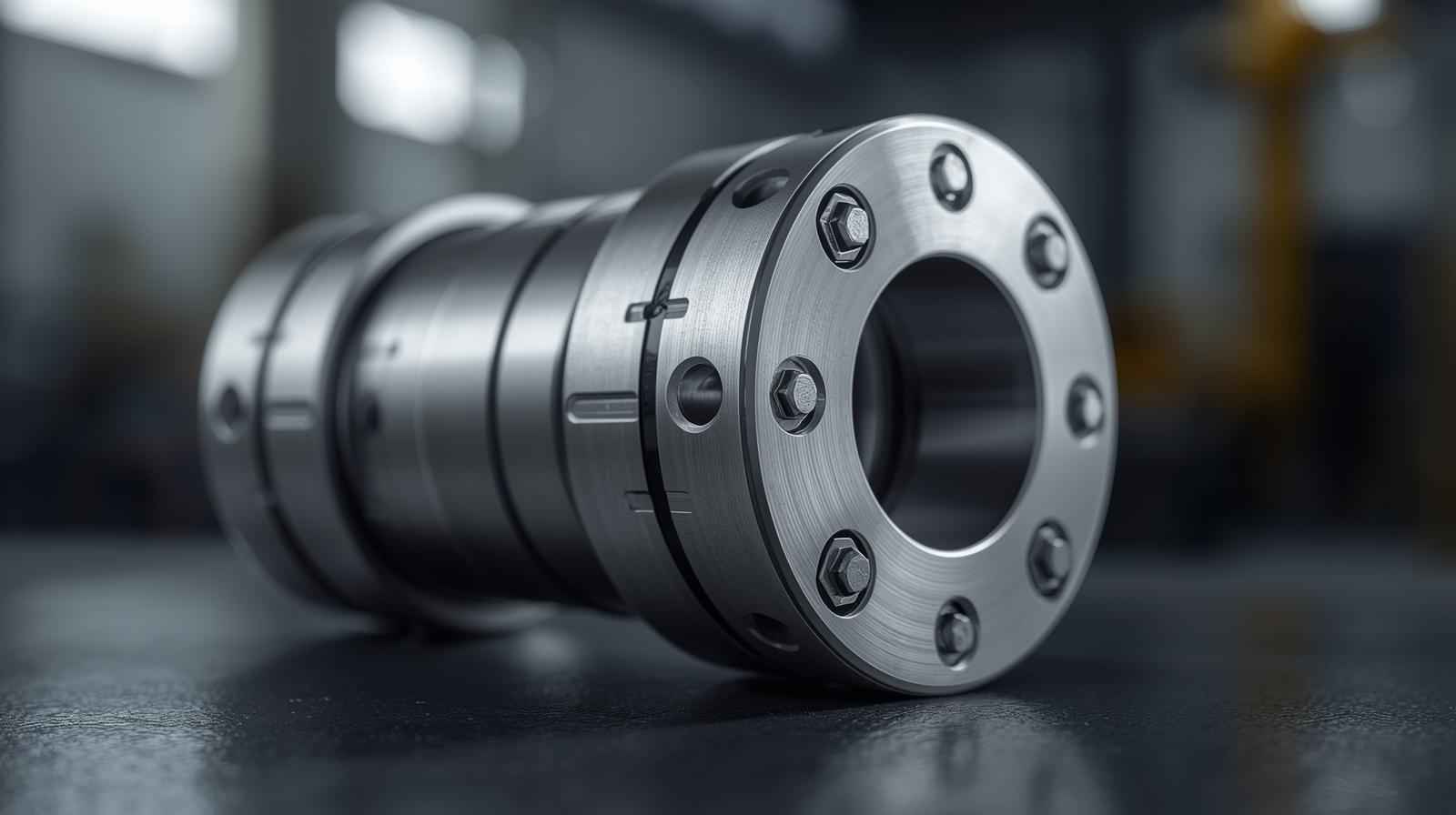

Rigid couplers are designed for direct torque transmission without flexibility, making dimensional accuracy and shaft fitment critical.

In many industrial setups, mismatched bore sizes or incompatible hub lengths can create concentricity errors, reducing machine performance and accelerating wear.

Typical challenges solved by customization include:

-

Non-standard motor shaft diameters

-

Unique torque or speed requirements

-

Compact installation spaces

-

High-temperature or corrosive environments

-

Multi-axis synchronization needs

By adapting coupling geometry, materials, and surface treatments, manufacturers like Dingjian ensure that torque delivery remains consistent even under demanding conditions.

From Standard Models to Custom Engineering Solutions

While standard rigid couplers serve well in generic equipment, high-value systems — like CNC spindles, precision lathes, or robotics arms — require tighter tolerances and special hub configurations.

Dingjian offers an end-to-end customization workflow:

| Step | Process | Outcome |

|---|---|---|

| 1 | Application Consultation | Torque, bore, and layout analysis |

| 2 | CAD & 3D Modelling | Exact geometry design |

| 3 | Material Selection | Steel, aluminum, or stainless alloys |

| 4 | CNC Machining & Balancing | ISO G2.5 precision standard |

| 5 | Testing & Certification | Torque load, concentricity, and runout validation |

This ensures that every custom coupler meets both mechanical accuracy and operational durability standards across industries.

Comparing Standard vs. Custom Rigid Couplers

| Feature | Standard Coupler | Custom Coupler (Dingjian) |

|---|---|---|

| Bore Fit | Limited fixed sizes | Match-to-order tolerance |

| Torque Rating | General-purpose | Application-calibrated |

| Material | Standard steel | Alloy or lightweight options |

| Length & Geometry | Fixed models | Adapted to installation limits |

| Balancing | Default | Dynamic ISO G2.5 certified |

| Performance | Average | Optimized precision and lifespan |

Unlike catalog-supplied components, Dingjian’s couplers are tuned to your motor dynamics, inertia ratio, and system resonance, reducing downtime and misalignment risk.

Real-World Applications Across Industrial Sectors

Custom rigid couplers find use wherever rotational precision and reliability are key:

-

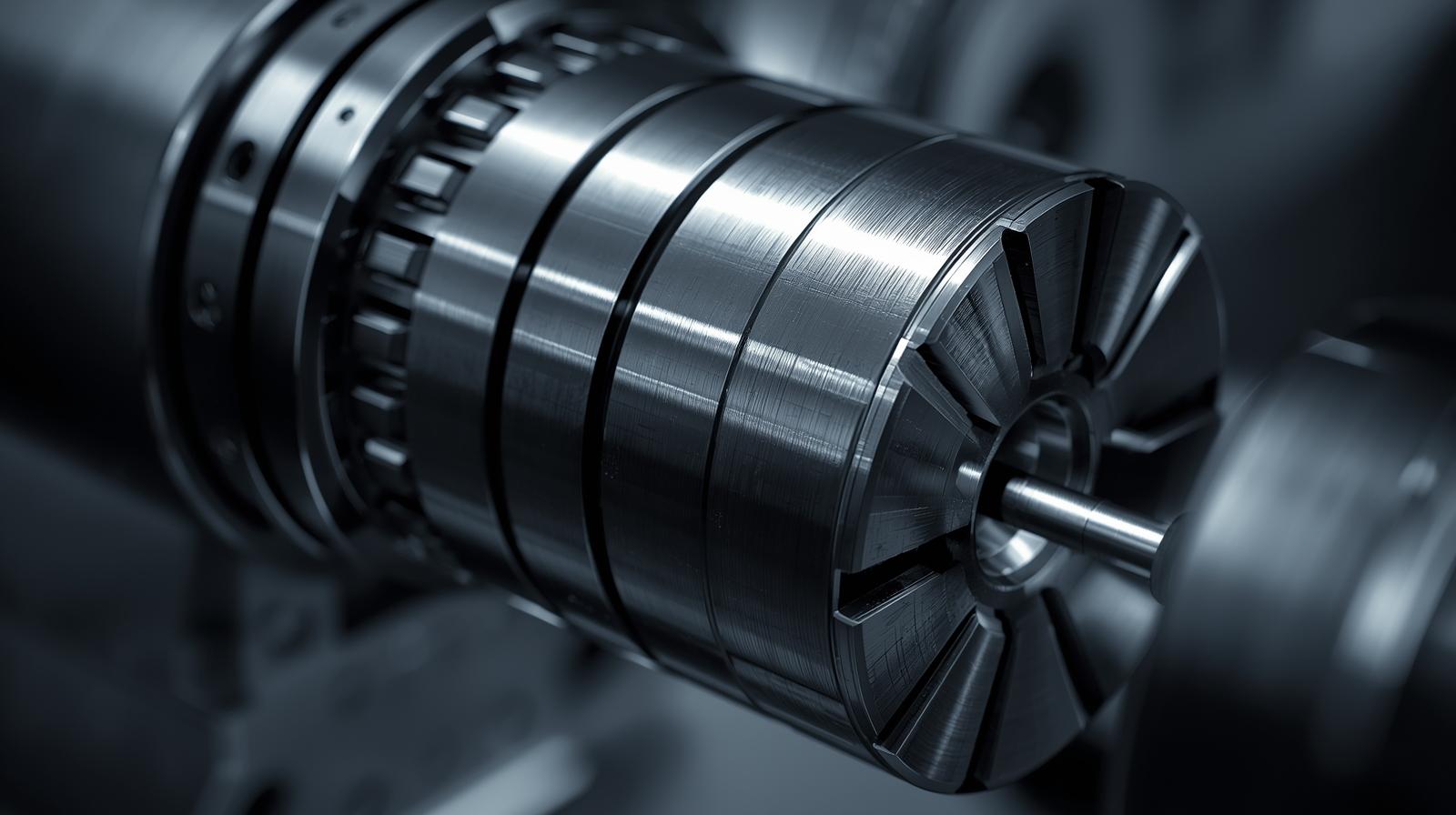

CNC machining centers – precise torque control during tool changes

-

Robotics – stable motion transfer for synchronized axes

-

Metallurgy & rolling mills – endurance under high torque and temperature

-

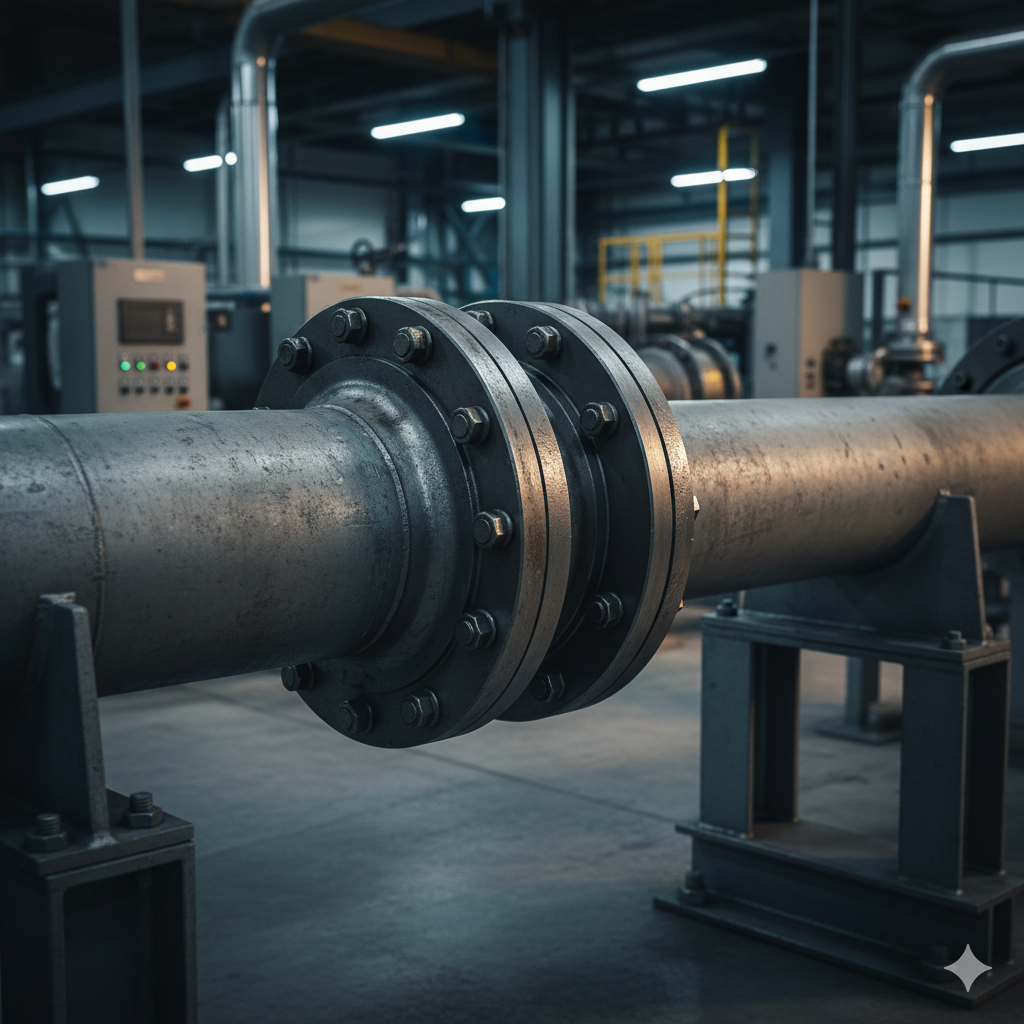

Material handling equipment – compact torque connectors for conveyors

-

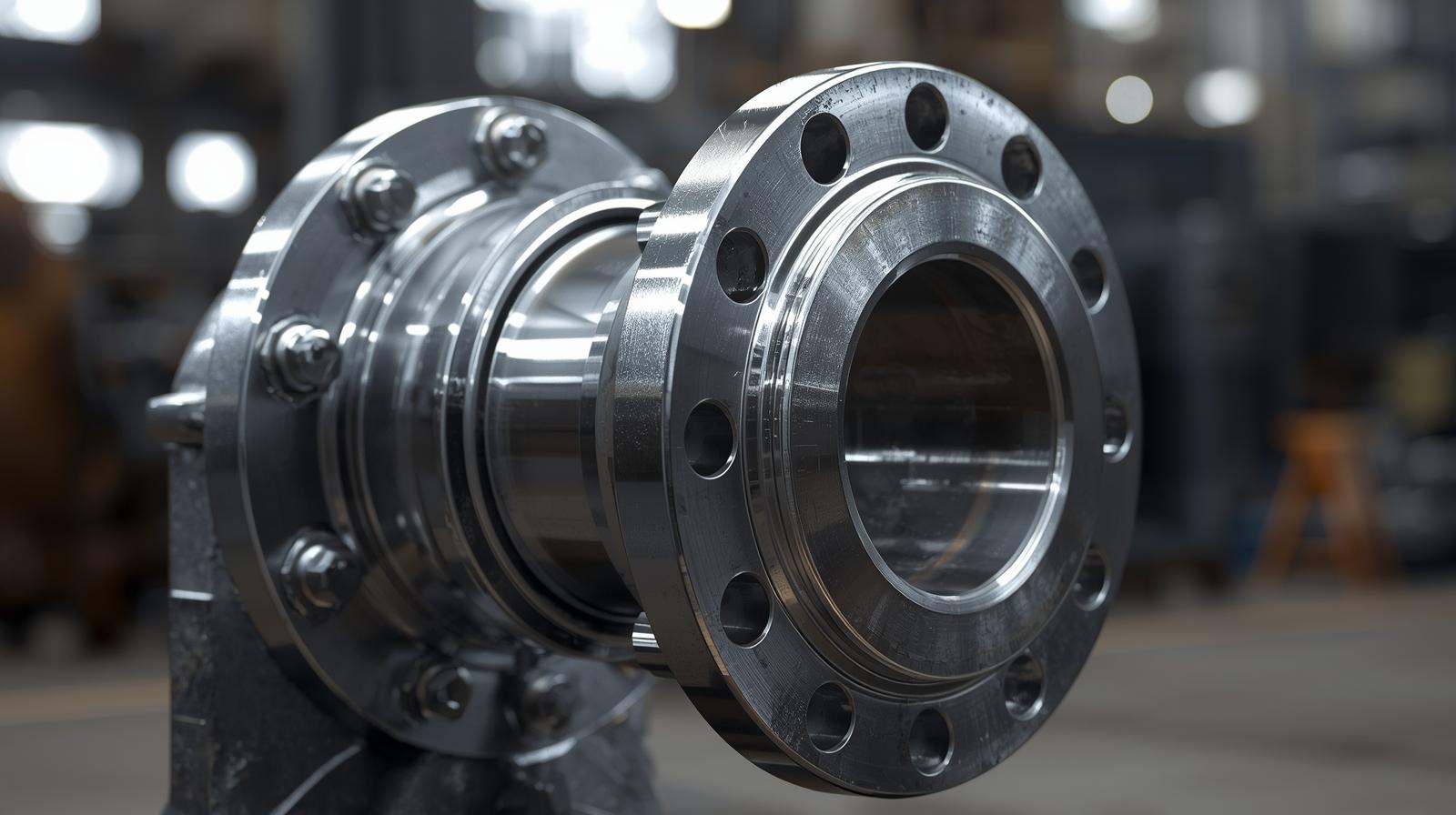

Pump and compressor drives – shaft coupling with anti-slip performance

These applications all share a single requirement: accurate, backlash-free torque delivery, even under variable speed and high load.

How to Specify the Right Custom Rigid Coupler

| Criterion | Consideration | Recommended Approach |

|---|---|---|

| Torque & Load | Determine rated torque and peak load cycles | Use alloy steel couplers for heavy load |

| Speed & Balance | Assess operational RPM | Choose dynamically balanced design (ISO G2.5) |

| Bore Tolerance | Identify motor/shaft diameters | Apply H7/h6 precision fit |

| Installation Space | Check available assembly length | Select compact or flanged geometry |

| Environment | Exposure to corrosion or heat | Opt for stainless steel or anodized finish |

By clarifying these factors early, buyers ensure custom orders align perfectly with drive system architecture.

Common Technical Questions

Q1: How long does custom coupling production take?

Typically 10–15 working days, depending on bore complexity and material stock.

Q2: What surface treatments are available?

Black oxide, nickel plating, or hard anodizing for corrosion and wear resistance.

Q3: Can Dingjian design couplers for retrofitting existing machines?

Yes, reverse-engineering service is available from sample or drawing.

Q4: Do custom couplers maintain ISO tolerance levels?

All products comply with ISO G6.3–G2.5 balancing and concentricity ≤0.01 mm.

The Precision Link Between Power and Performance

Custom rigid couplers are not just connectors — they are the mechanical bridge between accuracy and efficiency.

Dingjian’s customized manufacturing approach ensures every coupling achieves seamless torque flow, minimal vibration, and longer operational life.

To discuss your specific application or request a quote, please visit the official homepage or reach out via the contact page.