Introduction to Small Size Flexible Couplings in Robotics

In the rapidly evolving world of robotics, the small size flexible coupling for robotics stands out as a crucial component that bridges the gap between precision and adaptability. These compact devices connect shafts in robotic systems, allowing for smooth transmission of motion while accommodating misalignments and vibrations. Designed for space-constrained applications, a small size flexible coupling for robotics ensures that even the most intricate mechanisms operate with minimal backlash and high efficiency. As robotics continues to permeate industries like manufacturing, healthcare, and automation, selecting the right coupling becomes essential for achieving reliable performance. This article delves into the features, benefits, and applications of these innovative connectors, highlighting why they are indispensable in modern robotic designs.

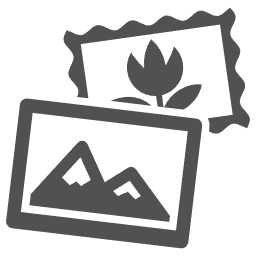

Key Features of Small Size Flexible Couplings

The engineering behind a small size flexible coupling for robotics focuses on delivering zero backlash and exceptional torsional stiffness, which are vital for precise motion control. One of the standout features is its dynamic torque transfer capability, enabling seamless power transmission without energy loss. This is particularly important in servo motor setups, where even slight deviations can compromise accuracy. Crafted from high-quality materials, these couplings incorporate advanced designs like harmonic drive elements to dampen vibrations and compensate for angular or parallel misalignments. For instance, in robotic arms, the small size flexible coupling for robotics handles negation of forces and veer corrections, ensuring the system maintains alignment under dynamic loads. Additionally, their compact form factor—often no larger than a few centimeters—makes them ideal for integration into miniature robots or drones, where space is at a premium. Reliability is another hallmark, with these couplings built to withstand repetitive cycles and harsh environments, from dusty factory floors to sterile medical settings.

Applications Across Industries

Versatility defines the small size flexible coupling for robotics, making it a go-to solution for a broad spectrum of industries. In robotics, these couplings excel in joint mechanisms, providing smooth and accurate motion for tasks like pick-and-place operations or surgical procedures. The medical technology sector benefits from their precision, as they enable delicate instrument manipulations in robotic-assisted surgeries, minimizing risks to patients. Automation lines in manufacturing rely on them to synchronize conveyor systems and robotic grippers, boosting throughput without mechanical failures. Even in the printing industry, where fine adjustments are needed for high-speed presses, the small size flexible coupling for robotics ensures consistent torque delivery, reducing downtime and enhancing print quality. OEM applications further underscore their robustness; these couplings are customized for complex machinery, supporting everything from collaborative robots (cobots) to autonomous mobile robots (AMRs). By addressing critical factors like vibration damping and misalignment compensation, they extend the lifespan of robotic components, ultimately lowering maintenance costs.

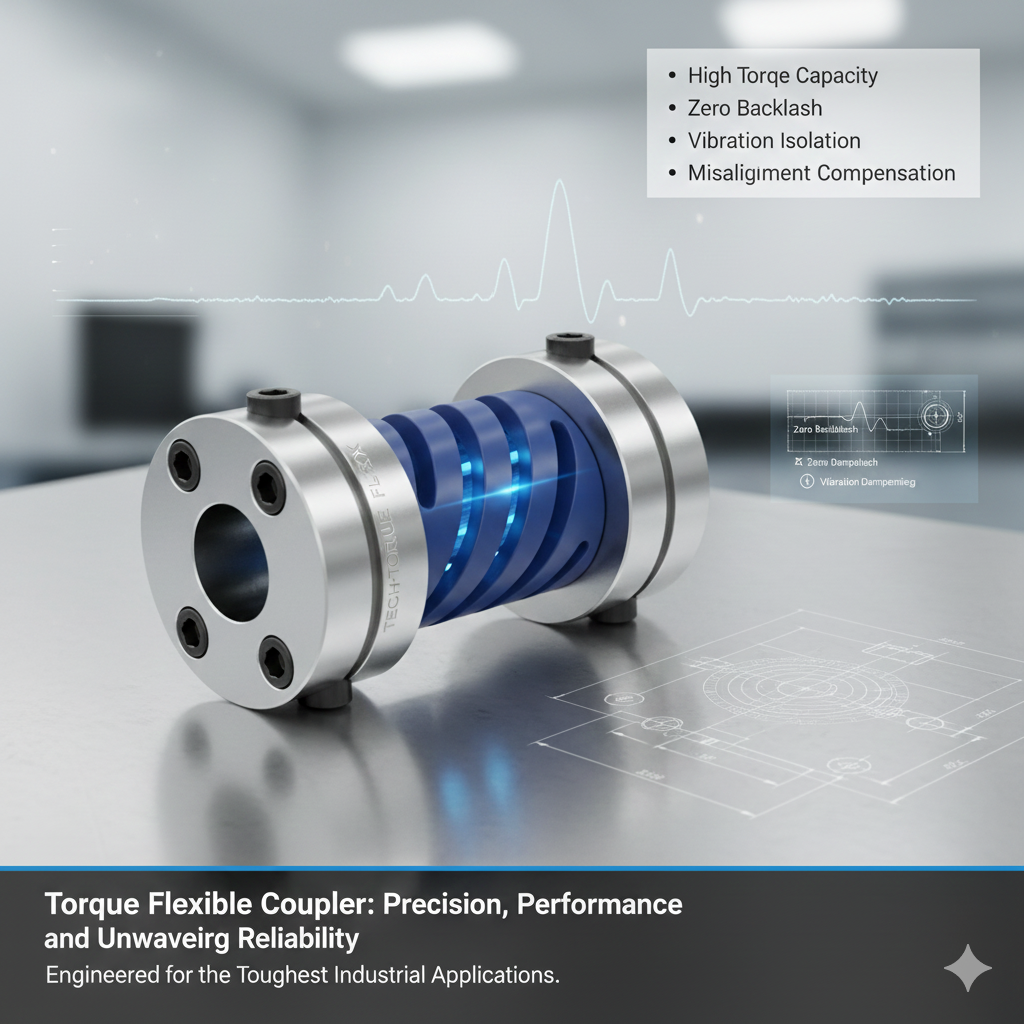

Advantages in Motion Control and Efficiency

What sets the small size flexible coupling for robotics apart is its ability to redefine standards in motion technology. With a focus on smooth accuracy, these connectors eliminate the common pitfalls of rigid couplings, such as stress concentrations that lead to premature wear. Their superior torsional stiffness translates to immediate response times in servo-driven systems, allowing robots to execute complex paths with pinpoint precision. In high-torque scenarios, the dynamic power transmission prevents slippage, maintaining efficiency even under varying loads. For robotics engineers, this means designing systems that are not only faster but also more energy-efficient, aligning with the push for sustainable manufacturing practices. Moreover, the couplings' adaptability to different shaft sizes and types—be it bellows, disc, or jaw styles—offers flexibility in prototyping and production. Durability is enhanced through corrosion-resistant coatings and fatigue-resistant alloys, ensuring optimal operation in challenging conditions like temperature fluctuations or chemical exposures. As a result, businesses adopting these couplings report improved system reliability, with fewer interruptions and higher overall productivity.

Choosing the Right Small Size Flexible Coupling

Selecting an appropriate small size flexible coupling for robotics requires careful consideration of several factors. Start by evaluating the torque requirements and operational speeds of your robotic application; couplings rated for high torsional loads will perform best in demanding environments. Misalignment tolerance is another key metric—opt for models that can handle up to 2 degrees of angular offset without compromising performance. Installation ease is crucial in compact robotics, so look for clamp-style or set-screw designs that allow quick assembly without specialized tools. Testing in real-world simulations can reveal how well the coupling manages vibrations, ensuring it integrates seamlessly with harmonic drives or gear reducers. Partnering with reputable suppliers who emphasize OEM customization can tailor the coupling to your exact specifications, incorporating features like integrated encoders for feedback loops. By prioritizing these aspects, robotics developers can harness the full potential of these connectors, fostering innovations that push the boundaries of what's possible in automated systems.

The Future of Flexible Couplings in Robotics

Looking ahead, the small size flexible coupling for robotics is poised to play a starring role in the next generation of intelligent machines. As AI-driven robotics advances, the demand for even smaller, smarter couplings will grow, integrating sensors for real-time monitoring of wear and alignment. This evolution promises enhanced adaptability, where robots can self-correct during operation, reducing human intervention. In industries like logistics, where agile robots navigate dynamic warehouses, these couplings will enable faster, more precise movements, optimizing supply chains. The commitment to precision and reliability in flexible shaft connectors underscores a future where motion control harmonizes with adaptability, driving efficiencies across sectors. For robotics enthusiasts and professionals alike, embracing these technologies means staying at the forefront of innovation, ensuring that every mechanical link contributes to a more connected and capable world. With ongoing advancements, the small size flexible coupling for robotics will continue to be a cornerstone of reliable, high-performance systems.