Discovering Excellence: Why Choose a Premier Universal Joint Manufacturer

In the world of mechanical engineering, finding a reliable universal joint manufacturer is crucial for ensuring seamless power transmission in various applications. A universal joint, often called a U-joint, is an essential component that allows for angular misalignment between connected shafts while transmitting rotary motion efficiently. As industries evolve, partnering with a top universal joint manufacturer guarantees access to high-quality products that meet stringent standards for durability and performance. This article explores the innovations and benefits of sourcing from a trusted universal joint manufacturer, highlighting how such expertise can elevate your projects.

The Engineering Marvel of Universal Joints

Universal joints are marvels of engineering, designed to handle complex motion requirements in machinery. A leading universal joint manufacturer focuses on crafting these components from robust materials like stainless steel, ensuring they withstand harsh environments and resist corrosion. The typical design includes two yokes or forks connected by a cross piece, with precision-engineered pins and circlips for secure assembly. This setup allows the joint to accommodate up to 30 degrees of misalignment, making it indispensable in automotive drivelines, industrial machinery, and even aerospace systems.

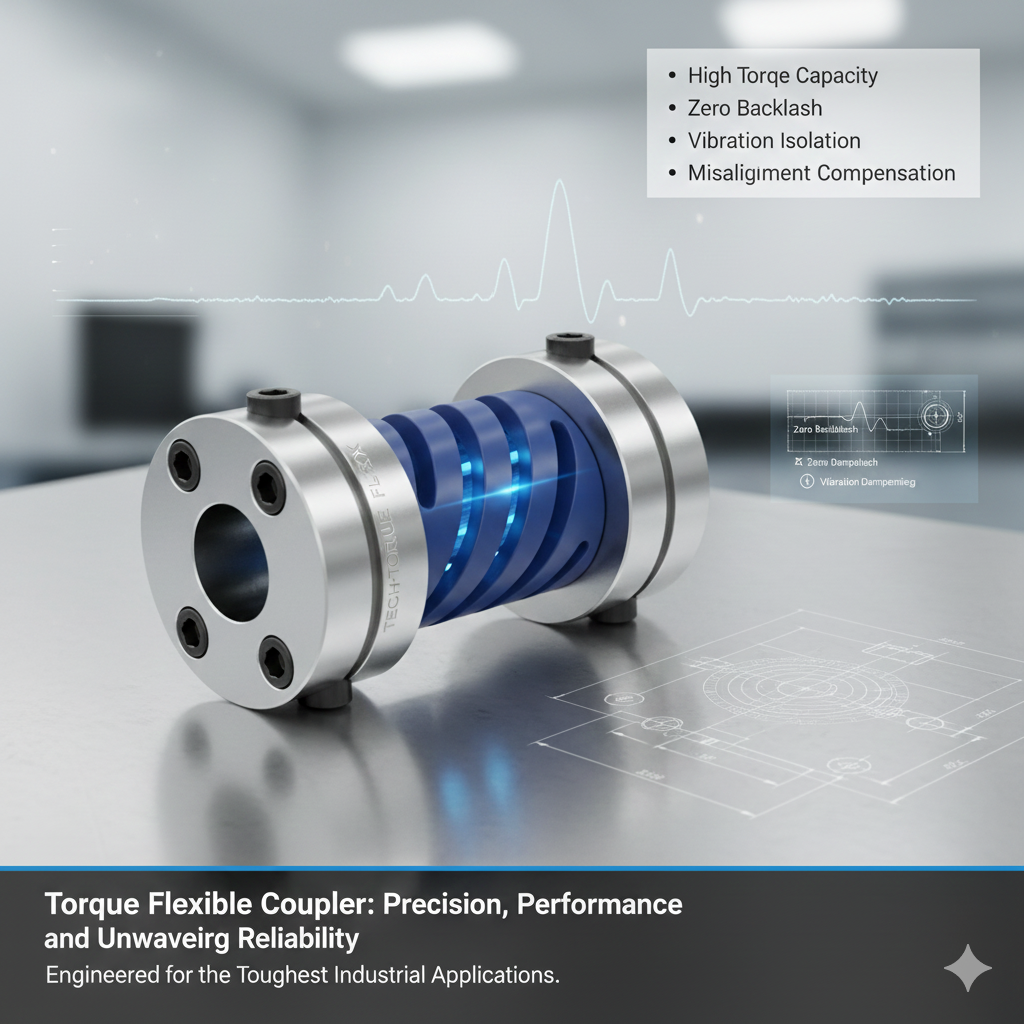

What sets products from a reputable universal joint manufacturer apart is their attention to detail. For instance, the smooth, polished finish not only enhances aesthetic appeal but also reduces friction and wear over time. These joints are built to transmit torque smoothly, minimizing vibrations and extending the lifespan of connected components. Whether you're assembling a heavy-duty tractor or a precision robotic arm, a quality universal joint from a skilled manufacturer ensures reliable operation without frequent maintenance.

Moreover, advancements in manufacturing techniques, such as CNC machining and heat treatment processes, allow a universal joint manufacturer to produce parts with tight tolerances. This precision translates to better alignment and efficiency, reducing energy loss in power transmission. Industries ranging from agriculture to marine applications benefit from these innovations, proving that selecting the right universal joint manufacturer can significantly impact overall system performance.

Applications and Versatility in Modern Industries

The versatility of universal joints makes them a go-to choice across multiple sectors, and a dedicated universal joint manufacturer tailors their offerings to these diverse needs. In the automotive industry, for example, these joints are integral to driveshafts, enabling vehicles to navigate turns without power interruption. A universal joint manufacturer with expertise in this area ensures their products can handle high-speed rotations and varying loads, contributing to safer and more efficient driving experiences.

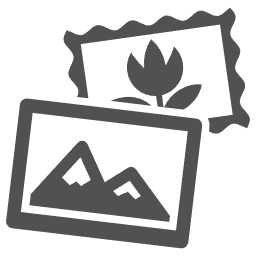

Beyond vehicles, universal joints shine in industrial machinery. Factories rely on them for conveyor systems, pumps, and mixers where shafts must connect at non-linear angles. By choosing a universal joint manufacturer committed to quality, businesses can avoid costly downtimes caused by joint failures. In robotics, these components facilitate flexible movement in multi-axis arms, supporting automation in manufacturing lines. The compact design of modern universal joints, often featuring needle bearings for smoother operation, allows integration into space-constrained environments without sacrificing strength.

Custom applications also highlight the prowess of a top universal joint manufacturer. For marine propulsion systems, joints must endure saltwater exposure, prompting manufacturers to use corrosion-resistant alloys. In renewable energy setups like wind turbines, universal joints manage angular adjustments due to wind variability. This adaptability underscores why partnering with a universal joint manufacturer who understands specific industry demands is essential for innovation and reliability.

Quality Assurance and Manufacturing Excellence

When selecting a universal joint manufacturer, quality assurance processes are paramount. Reputable manufacturers adhere to international standards like ISO 9001, conducting rigorous testing for torque capacity, fatigue resistance, and dimensional accuracy. This ensures that every universal joint delivered performs consistently under real-world conditions. From raw material selection to final inspection, the journey involves advanced tools like spectrometers for material composition checks and dynamic testing rigs to simulate operational stresses.

Sustainability is another focus for forward-thinking universal joint manufacturers. By optimizing production methods, they reduce waste and energy consumption, appealing to eco-conscious clients. For instance, using recyclable stainless steel and efficient machining minimizes environmental impact while maintaining product integrity. A universal joint manufacturer that prioritizes these practices not only meets regulatory requirements but also aligns with global trends toward green engineering.

Customer support further differentiates elite universal joint manufacturers. They offer customization options, such as varying sizes from miniature to heavy-duty models, and provide technical guidance for integration. This collaborative approach helps engineers overcome design challenges, ensuring the final assembly functions optimally. Investing in products from such a manufacturer means gaining a partner dedicated to your success, backed by warranties and post-sale services.

The Future of Universal Joint Technology

Looking ahead, the role of a universal joint manufacturer in driving technological progress is undeniable. Emerging trends like Industry 4.0 integrate smart sensors into joints for real-time monitoring of wear and alignment, preventing failures proactively. A innovative universal joint manufacturer is already exploring these enhancements, combining traditional mechanics with IoT capabilities to create 'smart' joints that communicate data via wireless networks.

Material science advancements promise even greater durability. Composites and advanced alloys could replace traditional metals in certain applications, offering lighter weight without compromising strength. For electric vehicles, where efficiency is key, universal joint manufacturers are developing low-friction designs to maximize battery range. These evolutions position a forward-looking universal joint manufacturer at the forefront of mechanical innovation.

In conclusion, choosing the right universal joint manufacturer is about more than just components—it's about securing reliability, efficiency, and future-proofing your operations. With a commitment to precision craftsmanship and customer needs, these manufacturers empower industries to thrive. Whether upgrading existing systems or pioneering new designs, rely on a trusted universal joint manufacturer to deliver the excellence your projects demand. As mechanical demands grow more complex, the expertise of such partners will continue to be invaluable.