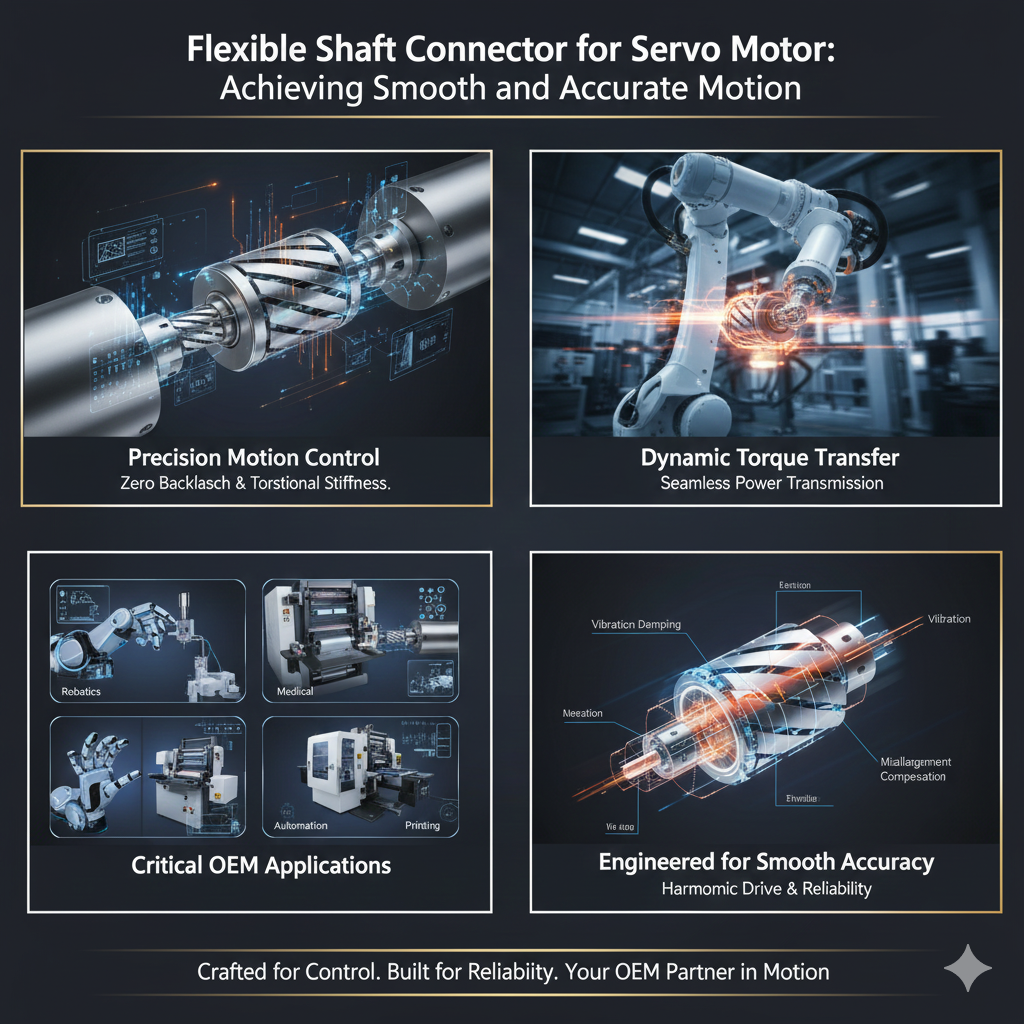

Understanding the Industrial Power Transmission Joint: A Key to Precision Engineering

In the world of mechanical engineering, the industrial power transmission joint stands out as a critical component for ensuring seamless power transfer in complex systems. This high-performance coupling is designed specifically for precision applications, boasting a remarkable torque capacity of 1500 Nm that makes it ideal for demanding industrial setups. Whether you're dealing with heavy machinery or intricate robotic assemblies, integrating an industrial power transmission joint can significantly enhance operational efficiency and reliability.

Key Features of the Industrial Power Transmission Joint

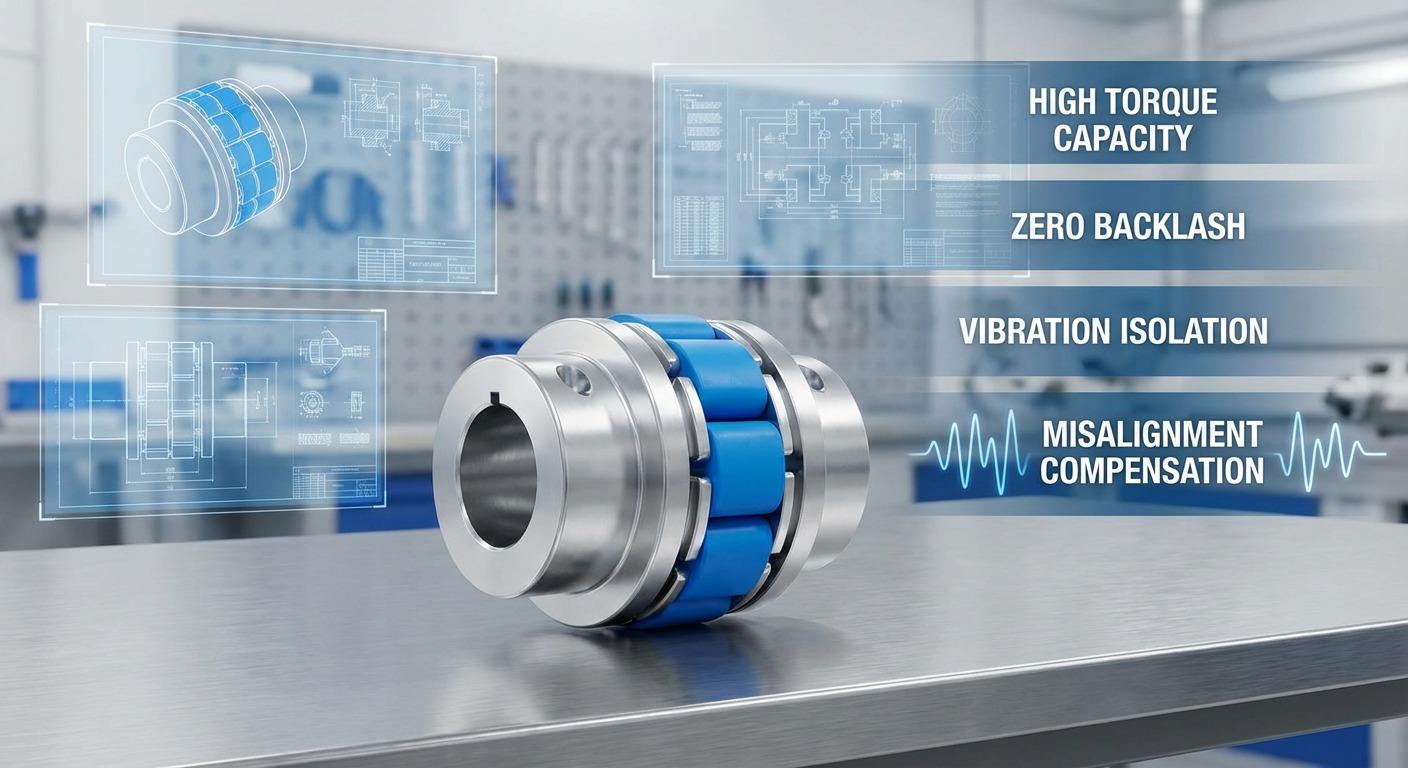

One of the standout attributes of the industrial power transmission joint is its exceptional vibration isolation, exceeding 95%. This feature is essential in environments where excessive vibrations can lead to premature wear, noise pollution, and reduced accuracy. By dampening these vibrations effectively, the joint promotes smoother operations, allowing machinery to run quieter and with less stress on surrounding components. This not only extends the lifespan of the equipment but also minimizes maintenance costs over time.

Additionally, the zero backlash design of this industrial power transmission joint ensures unparalleled accuracy and repeatability in motion control. In precision tasks, even the slightest play can result in errors that compound over operations, leading to inefficiencies or failures. The joint's construction eliminates this issue, providing a direct and responsive connection between shafts. This is particularly beneficial in automated systems where consistent performance is non-negotiable.

Misalignment Compensation and Installation Flexibility

Flexibility is another hallmark of the industrial power transmission joint, thanks to its advanced misalignment compensation capabilities. It can handle angular offsets of up to ±2 degrees and parallel offsets of ±1mm without compromising performance. This tolerance is a game-changer during installation, as it accommodates minor alignment imperfections that are common in real-world assembly scenarios. Engineers no longer need to spend excessive time achieving perfect alignment, reducing setup times and potential errors.

In practical terms, this means the industrial power transmission joint can adapt to dynamic conditions within machinery, such as thermal expansions or slight shifts due to operational loads. For industries like manufacturing and automation, where equipment might experience varying stresses, this adaptability ensures sustained reliability. The joint's ability to maintain power transmission integrity under these conditions underscores its value in high-stakes applications.

Applications in Advanced Industries

The industrial power transmission joint finds its true calling in sectors where precision and durability are paramount, such as robotics, aerospace, and heavy industrial automation. In robotic arms, for instance, the joint's high torque capacity and zero backlash enable precise movements essential for tasks like assembly or welding. This level of control translates to higher productivity and fewer defects in production lines.

Beyond robotics, consider its role in conveyor systems or CNC machines. Here, the vibration isolation helps protect sensitive components from harmonic disturbances, ensuring consistent output. The joint's robust construction, combined with its sleek design, also contributes to a more compact integration, which is advantageous in space-constrained environments. Overall, adopting this technology can lead to significant improvements in system efficiency and longevity.

Benefits for Long-Term Performance and Efficiency

Investing in an industrial power transmission joint offers more than just immediate operational gains; it delivers long-term benefits that align with modern engineering goals. The reduced wear from vibration dampening means fewer unexpected downtimes, which is crucial for maintaining production schedules in competitive markets. Moreover, the joint's efficiency in power transmission—without energy losses due to misalignment—can lower overall energy consumption, supporting sustainability initiatives.

From a design perspective, the industrial power transmission joint's versatility allows engineers to innovate bolder solutions. It supports the integration of advanced materials and technologies, pushing the boundaries of what's possible in mechanical systems. For companies aiming to stay ahead, incorporating such components is not just an upgrade but a strategic move toward enhanced performance and cost savings.

Why Choose This Coupling for Your Next Project

When selecting components for precision applications, the industrial power transmission joint emerges as a superior choice due to its blend of strength, accuracy, and adaptability. With a torque handling of 1500 Nm and over 95% vibration isolation, it addresses the core challenges of modern machinery. Its zero backlash and misalignment tolerance further solidify its position as a reliable solution for demanding tasks.

Engineers and project managers will appreciate how this joint simplifies design and installation while maximizing output. In an era where downtime is costly and precision is king, the industrial power transmission joint provides the edge needed to excel. Whether upgrading existing systems or embarking on new developments, this coupling promises durability, efficiency, and exceptional performance that drive success.

In summary, the industrial power transmission joint is more than a connector—it's a cornerstone of advanced engineering. By leveraging its capabilities, industries can achieve smoother, more reliable operations that stand the test of time. As technology evolves, components like this will continue to play a pivotal role in shaping the future of mechanical innovation.