Understanding the Role of an Industrial Coupling Supplier in Modern Manufacturing

As industries evolve, finding a reliable industrial coupling supplier becomes crucial for maintaining operational efficiency. An industrial coupling supplier provides essential components that connect rotating shafts in machinery, ensuring seamless power transmission and alignment. These suppliers offer a range of products tailored to various applications, from light-duty equipment to heavy industrial systems. By partnering with a trusted industrial coupling supplier, businesses can access high-quality couplings that minimize downtime and enhance productivity. In today's fast-paced manufacturing landscape, the expertise of an industrial coupling supplier is invaluable for selecting the right solution that meets specific torque and speed requirements.

Exploring High-Strength Flange Couplings from Your Industrial Coupling Supplier

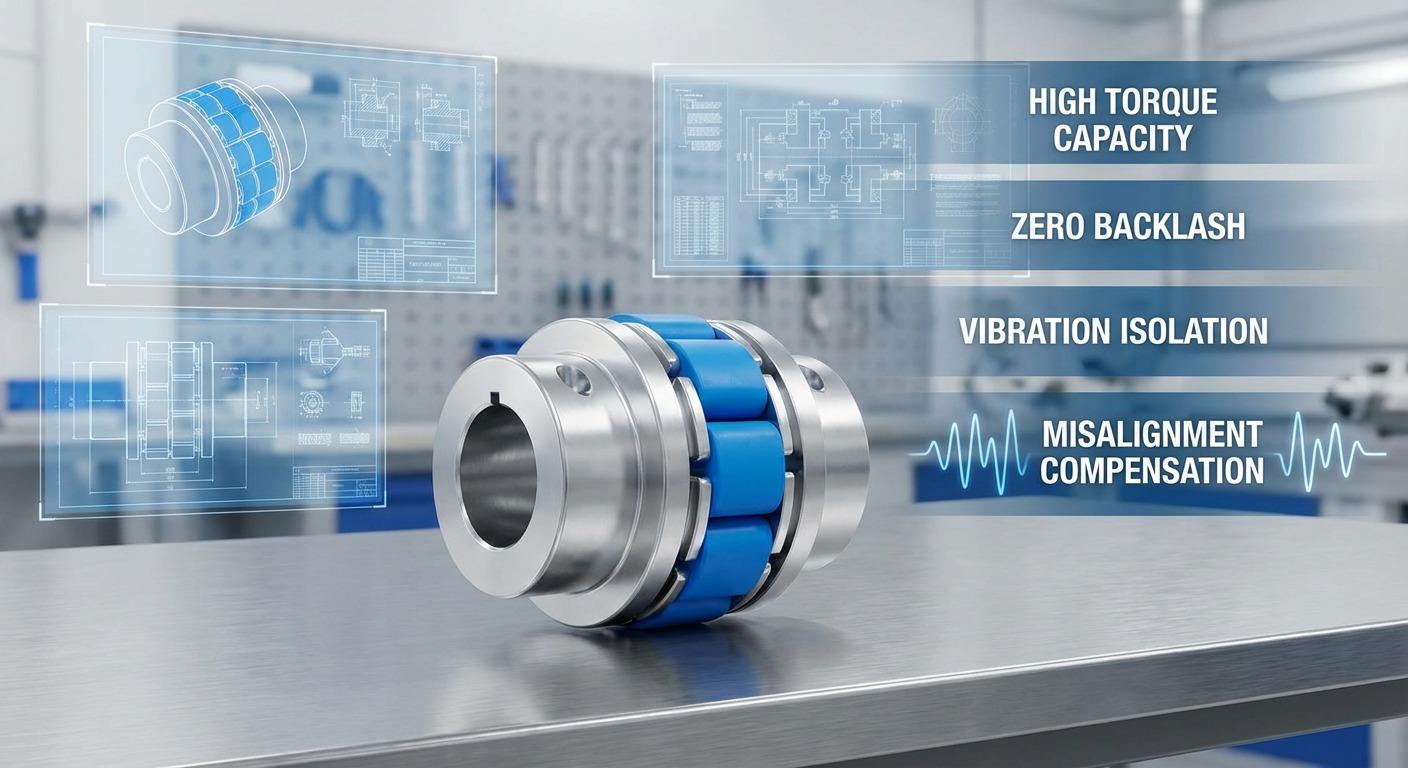

One standout product from a reputable industrial coupling supplier is the high-strength flange coupling, engineered for demanding environments. This coupling features precision-machined components made from durable, polished steel, providing unparalleled strength and reliability. The design allows for seamless integration between shafts, facilitating efficient torque transmission while maintaining precise alignment. With a series of evenly spaced bolts, it ensures secure fastening even under high-pressure conditions, effectively reducing vibration and noise that can lead to equipment wear. As an industrial coupling supplier, we prioritize these features to deliver components that withstand rigorous use in sectors like manufacturing and energy production.

Key Benefits of Sourcing from a Professional Industrial Coupling Supplier

Choosing the right industrial coupling supplier offers numerous advantages, starting with access to corrosion-resistant materials that extend the lifespan of your machinery. High-strength flange couplings, for instance, boast a sleek finish that not only enhances aesthetics but also protects against environmental factors such as moisture and chemicals. This durability translates to lower maintenance costs and fewer unexpected breakdowns. Moreover, a dedicated industrial coupling supplier provides customization options, allowing you to tailor couplings to your exact specifications—whether for high-torque applications in pumps or flexible connections in conveyor systems. By relying on an experienced supplier, you ensure compliance with industry standards, boosting overall system integrity and safety.

Applications of Flange Couplings in Heavy-Duty Industries

In heavy-duty manufacturing, the high-strength flange coupling supplied by a quality industrial coupling supplier proves indispensable. These couplings are ideal for connecting motors to pumps in water treatment facilities, where consistent performance is non-negotiable. Their robust construction handles the stresses of continuous operation, transmitting power without slippage or misalignment. Similarly, in critical infrastructure projects like power generation plants, flange couplings from a reliable industrial coupling supplier manage high loads and vibrations, ensuring smooth energy transfer. The ability to accommodate axial and radial movements makes them versatile for diverse setups, from automotive assembly lines to mining equipment. Businesses that source from a trusted industrial coupling supplier report improved efficiency and reduced operational risks.

Why Precision Engineering Matters in Industrial Couplings

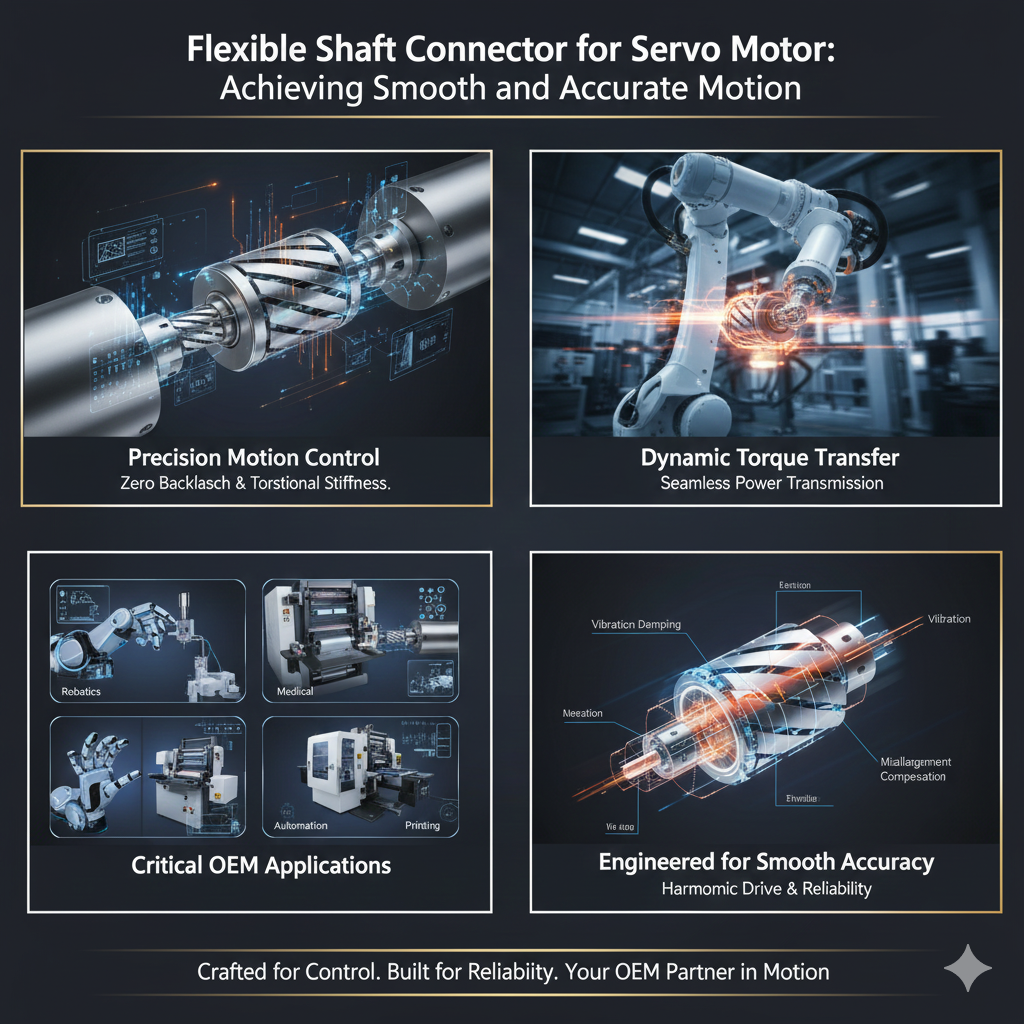

Precision engineering is at the heart of every product from a leading industrial coupling supplier, particularly in the design of high-strength flange couplings. The manufacturing process involves advanced techniques to achieve tight tolerances, ensuring that each coupling fits perfectly without the need for extensive adjustments. This level of accuracy minimizes energy loss during transmission and prevents premature failure. An industrial coupling supplier with a focus on quality control conducts rigorous testing, including torque and fatigue assessments, to guarantee performance under real-world conditions. For industries dealing with high-speed rotations, such as in aerospace or textile machinery, this precision is critical to avoiding catastrophic breakdowns. Partnering with an industrial coupling supplier committed to engineering excellence means investing in long-term reliability.

Maintaining and Selecting Couplings from Your Industrial Coupling Supplier

Proper maintenance is key to maximizing the value of components from an industrial coupling supplier. Regular inspections of high-strength flange couplings can detect early signs of wear, such as bolt loosening or surface corrosion, allowing for timely interventions. An experienced industrial coupling supplier often provides guidelines and support for upkeep, including lubrication recommendations to keep moving parts smooth. When selecting a coupling, consider factors like shaft size, load capacity, and environmental exposure—details that a knowledgeable industrial coupling supplier can help navigate. By choosing the appropriate type, such as rigid flange designs for aligned systems or flexible variants for misalignment tolerance, you optimize your machinery's performance. This proactive approach, guided by an industrial coupling supplier, ensures sustained productivity across operations.

The Future of Industrial Couplings and Supplier Innovations

Looking ahead, innovations from forward-thinking industrial coupling suppliers are set to revolutionize the field. Advances in materials, like composite alloys, promise even greater strength-to-weight ratios for high-strength flange couplings, making them suitable for emerging technologies in renewable energy. An industrial coupling supplier at the forefront of these developments offers eco-friendly options that reduce energy consumption and environmental impact. As automation and IoT integration grow, suppliers are incorporating smart features, such as sensors for real-time monitoring of coupling health. This evolution underscores the importance of selecting an industrial coupling supplier that invests in R&D, ensuring your operations remain competitive. By staying aligned with these trends, businesses can future-proof their equipment and drive innovation in their sectors.

In summary, a dependable industrial coupling supplier is more than a vendor—it's a partner in achieving mechanical excellence. From the robust performance of high-strength flange couplings to tailored solutions for specific needs, the right supplier empowers your industrial endeavors with reliability and efficiency.