Discover the Excellence of an OEM Coupling Manufacturer

In the world of industrial engineering, finding a reliable OEM coupling manufacturer is essential for ensuring seamless operations and durable performance. As industries evolve, the demand for high-quality couplings that can handle rigorous conditions has never been higher. An OEM coupling manufacturer specializes in producing custom and standard couplings tailored to specific mechanical needs, providing businesses with components that enhance efficiency and reliability. This expertise is particularly vital in sectors where precision and strength are non-negotiable.

Understanding the Role of an OEM Coupling Manufacturer

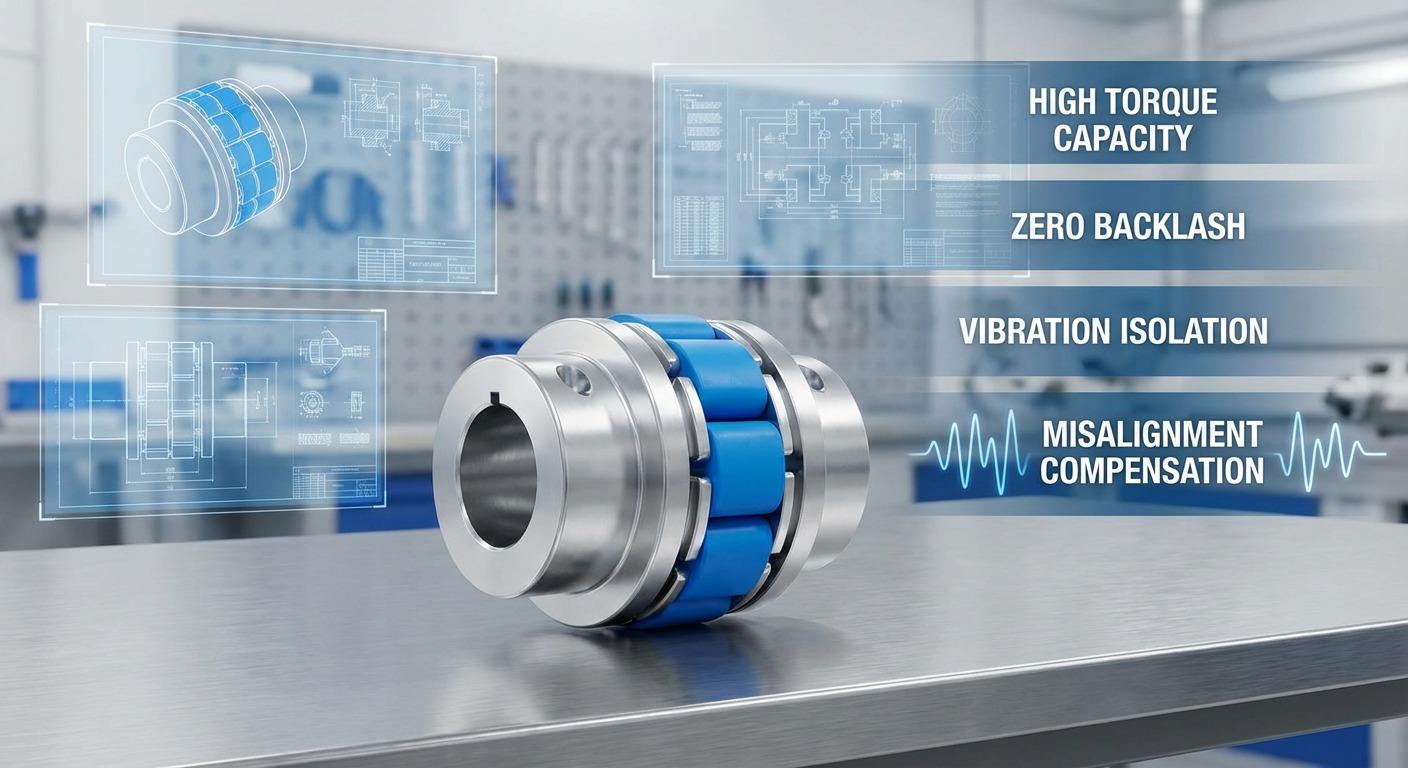

An OEM coupling manufacturer plays a pivotal role in the supply chain by designing and producing couplings that connect shafts in machinery, transmitting power while compensating for minor misalignments. These professionals use advanced materials and cutting-edge manufacturing techniques to create products that withstand extreme pressures, temperatures, and vibrations. For instance, couplings from a trusted OEM coupling manufacturer are often made from high-grade stainless steel or alloys that resist corrosion, ensuring long-term functionality in demanding environments like manufacturing plants or oil refineries.

The process begins with a deep understanding of client specifications. An OEM coupling manufacturer collaborates closely with engineers to develop prototypes, conduct rigorous testing, and refine designs for optimal performance. This customized approach sets them apart from generic suppliers, as it allows for innovations such as modular designs that facilitate easy installation and reduced downtime. By focusing on quality control at every stage, an OEM coupling manufacturer guarantees that their products meet international standards like ISO certifications, giving clients peace of mind.

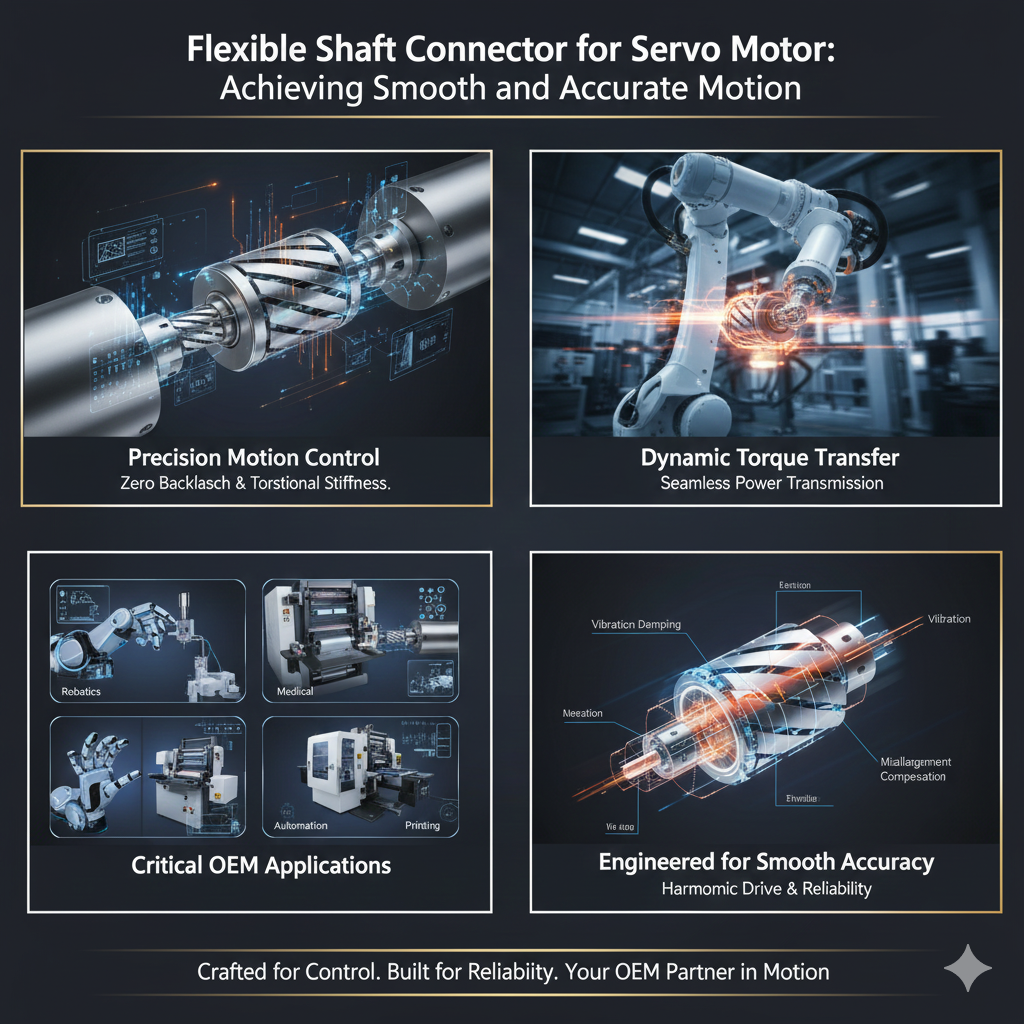

Moreover, the adaptability of products from an OEM coupling manufacturer extends to various types, including rigid, flexible, and fluid couplings. Rigid couplings are ideal for precise alignment in high-torque applications, while flexible ones absorb shocks in dynamic systems. This versatility makes an OEM coupling manufacturer a go-to partner for industries seeking tailored solutions that boost operational efficiency.

Spotlight on High Strength Flange Couplings

Among the standout offerings from a premier OEM coupling manufacturer is the High Strength Flange Coupling, an engineering marvel designed for maximum durability and reliability in industrial applications. This coupling showcases superior craftsmanship with its robust construction in high-grade, polished stainless steel. The precision machining ensures flawless alignment and fastening, ideal for high-performance tasks requiring secure and stable connections. As a product from an OEM coupling manufacturer, it exemplifies the commitment to excellence that defines top-tier production.

The flange coupling features an array of evenly distributed bolt holes, allowing for a secure fit to a variety of flange sizes. This adaptability is critical in environments where flexibility and strength are paramount. The polished finish not only provides an aesthetically pleasing look but also enhances resistance to corrosion and wear, ensuring longevity even in harsh conditions. Businesses relying on an OEM coupling manufacturer for such innovations benefit from components that minimize maintenance needs and extend equipment lifespan.

Engineered for ease of installation and maintenance, this high-strength flange coupling is perfect for sectors such as petrochemical, power generation, and heavy machinery where robust and dependable components are crucial. Achieve seamless transmission of torque and power with this cutting-edge flange coupling, setting new standards in industrial connectivity solutions. Partnering with an OEM coupling manufacturer ensures access to these advanced designs, which are rigorously tested to handle loads up to thousands of horsepower without failure.

Why Choose an OEM Coupling Manufacturer for Your Needs

Selecting the right OEM coupling manufacturer can significantly impact your project's success. These specialists offer not just products but comprehensive support, including technical consultations, rapid prototyping, and scalable production runs. Unlike off-the-shelf options, couplings from an OEM coupling manufacturer are built to exact specifications, reducing the risk of compatibility issues and enhancing overall system performance.

In today's competitive market, an OEM coupling manufacturer stands out by incorporating sustainable practices, such as using recyclable materials and energy-efficient manufacturing processes. This not only aligns with environmental regulations but also appeals to eco-conscious clients. Furthermore, their global reach allows for timely deliveries, minimizing supply chain disruptions. For example, in the automotive industry, an OEM coupling manufacturer provides couplings that improve fuel efficiency by reducing vibrational losses, demonstrating the practical value of their expertise.

The cost-effectiveness of sourcing from an OEM coupling manufacturer is another key advantage. While initial investments may seem higher, the durability and precision lead to lower long-term expenses through reduced repairs and replacements. Case studies from various industries show that companies switching to products from an OEM coupling manufacturer report up to 30% improvements in machinery uptime, underscoring the tangible benefits.

Future Trends in OEM Coupling Manufacturing

Looking ahead, an OEM coupling manufacturer is at the forefront of integrating smart technologies into their products. Imagine couplings embedded with sensors for real-time monitoring of alignment and wear, enabling predictive maintenance that prevents costly breakdowns. This innovation is driven by advancements in IoT and AI, areas where forward-thinking OEM coupling manufacturers are investing heavily.

Additionally, the push towards lightweight materials like carbon composites is reshaping the field. An OEM coupling manufacturer exploring these options can deliver couplings that reduce overall system weight without compromising strength, which is particularly beneficial in aerospace and renewable energy sectors. As automation grows, the demand for high-precision couplings will surge, positioning an OEM coupling manufacturer as an indispensable ally for innovation.

In conclusion, partnering with a reputable OEM coupling manufacturer ensures access to superior products like the High Strength Flange Coupling, backed by expert knowledge and unwavering quality. Whether you're upgrading existing machinery or designing new systems, these manufacturers provide the reliability needed to drive success in industrial applications.